Company:

ACE Geosynthetics Inc. Taichung City,

Project Details

Fabric 1

ACETube®

Producer:

ACE Geosynthetics Inc.

Design Company

Yong-Lin Engineering Consultants Co., Ltd.

Installation Company

Yu-Lun Construction Co., Ltd.

Please describe the project specifications

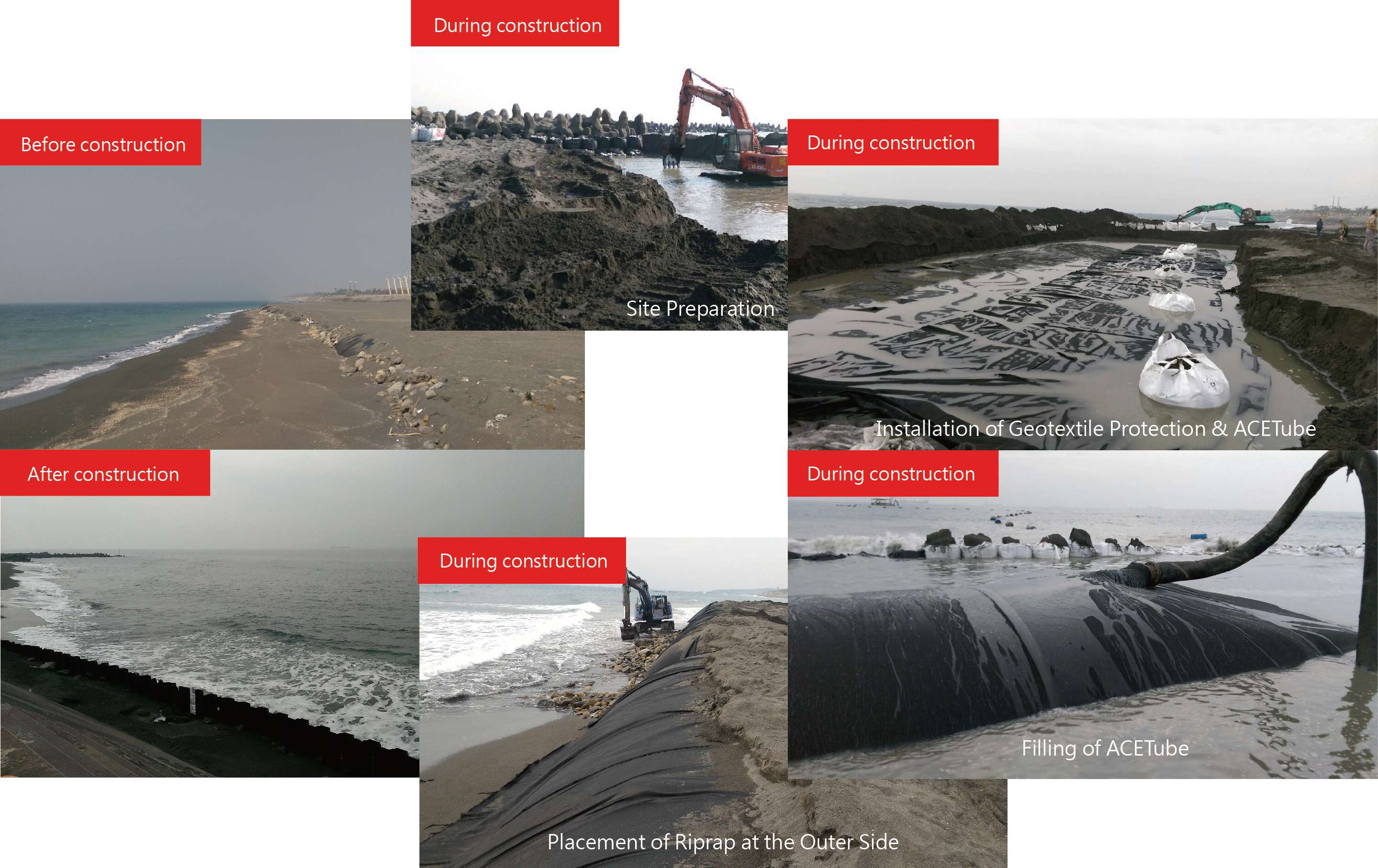

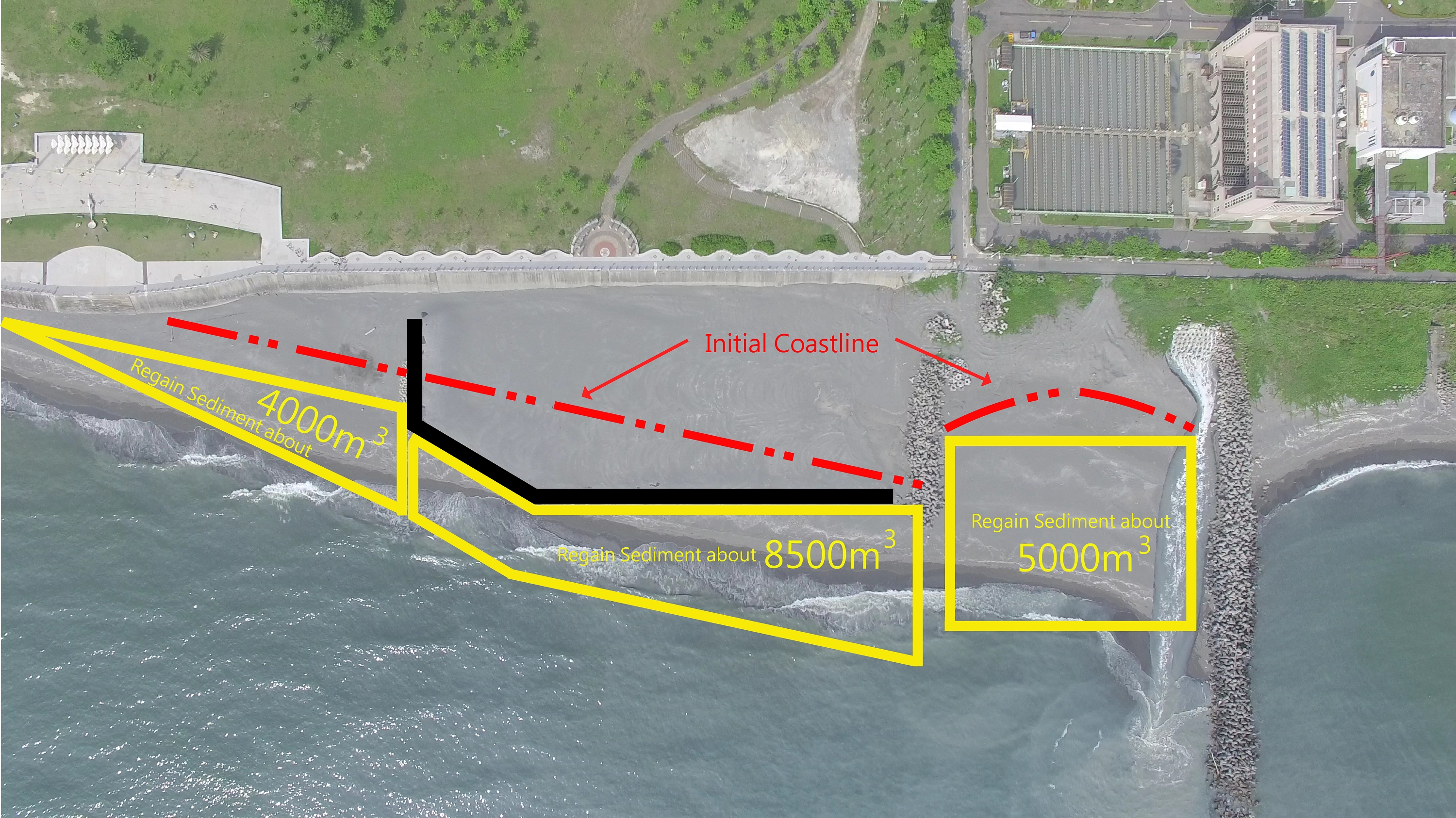

This project is a follow up construction for “Cijin Coastline Protection Program”. The site is located in Cijin, Kaohsiung, the most important harbor in Taiwan. The construction consisted of the installation of a sand barrier using geotextile ACETube® to connect with the existing groins. As shown in Figure 1, ACETube® has a dimension of 30m(W) x 140m(L) x 1.8m(H) and it was in parallel to the coastline with a distance of 75m apart. The construction was commenced in January and ended in February 2016. At the completion of geotube infilling, its surface from top to the outer sea side was immediately protected with 8m-long liner following with a layer of riprap (Figure 2). Hydraulic dredged sand from outer sea was then filled in to the retaining zone between the ACETube® barrier and the coastline. The contract specified volume of dredged backfill was 13,600m3. However, based on the monitoring of the site, two months after the completion of the work, there has been 17,500m3 sand actually regained at the site.

What was the purpose of this project? What did the client request?

Cijin, a southwest offshore island of Kaohsiung City, faces ocean with mountain behind. It is the origin of Kaohsiung maritime harbor. Its coastline terrain is relatively flat, straight and consists of fine sand only. During the past decade, the effects of summer typhoons, winter north-east high winds, tidal erosions, and short of refill from the upstream have made the coastline of Cijin faded away continuously. According to the monitoring results of Kaohsiung City Government (KCG), the accumulated area of the disappeared beach had been up to 300,000m2 during 2002~2012. Therefore, KCG issued a “Cijin Coastline Protection Program” in 2011 and aimed to introduce a composite protection technology that including practices of ecology and nourishment for the beach restoration. The construction installed offshore breakwaters to reduce the wave impact and improved the amount of refill of sand at the rear of the structures. The construction was completed in April 2013; however, the result of beach nourishment in a natural manner was not acceptable as anticipated. The designer thus proposed an improvement plan by using geotextile ACETube® to build a retaining zone near the breakwaters. It was then refilled with dredged sand directly from outer sea. ACETube® was installed in parallel to the shoreline between the offshore submerged breakwaters and the coastline. Once it was filled, it serves as an effective barrier to impede the scouring of sea bed and thus reduce the erosion of coastline. Because the drift sand was flowing from south to north, the retaining zone therefore caught the sand easily and made the beach nourishment efficiently within lesser time.

What is unique or complex about the project?

Although the initial “Cijin Coastline Protection Program” presented advantages of both ecological and natural nourishment for beach restoration, adverse environmental effects such as typhoon and wave scouring caused significant retreat of the shoreline. The result of beach nourishment in a natural manner was not acceptable as anticipated. Alternative solution was proposed by using ACETube® to build an additional retaining zone and filled in with dredged sand from outer sea. ACETube® was installed in parallel to the shoreline between the offshore submerged breakwaters and the coastline. Once it was filled, it serves as an effective barrier to impede the scouring of sea bed and thus reduce the erosion of coastline. Because the drift sand was flowing from south to north, the retaining zone therefore caught the sand easily and made the beach nourishment efficiently within lesser time. The successful of this project has promoted such technology becomes a demonstration solution for other similar sites.

What were the results of the project?

The construction was completed in February 2016. The result of monitoring for the restoration of coastline has indicated that there has no sand loss observed at the site after two months of the completion of the work. The ACETube® has been almost covered entirely by beach sand and the outside of the ACETube® also has regained about 17,500m3 of drifted sand (Figure 3). The ACE solution has proved to be successful for the nourishment of the beach for this project.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG