Company:

Fabritecture (UFS Australasia Pty Ltd T/A Fabritecture) Gold Coast, QLD

Project Details

Fabric 1

ETFE

Producer:

AGC

Supplier:

AGC

Engineer Company 1

Maffeis

Design Company

Fabritecture

Architect Company

Denton Corker Marshall

Fabrication Company

Seele Covertex

Subcontractor Company

Fabritecture

Project Manager Company

Fabritecture

Installation Company

Fabritecture

Please describe the project specifications

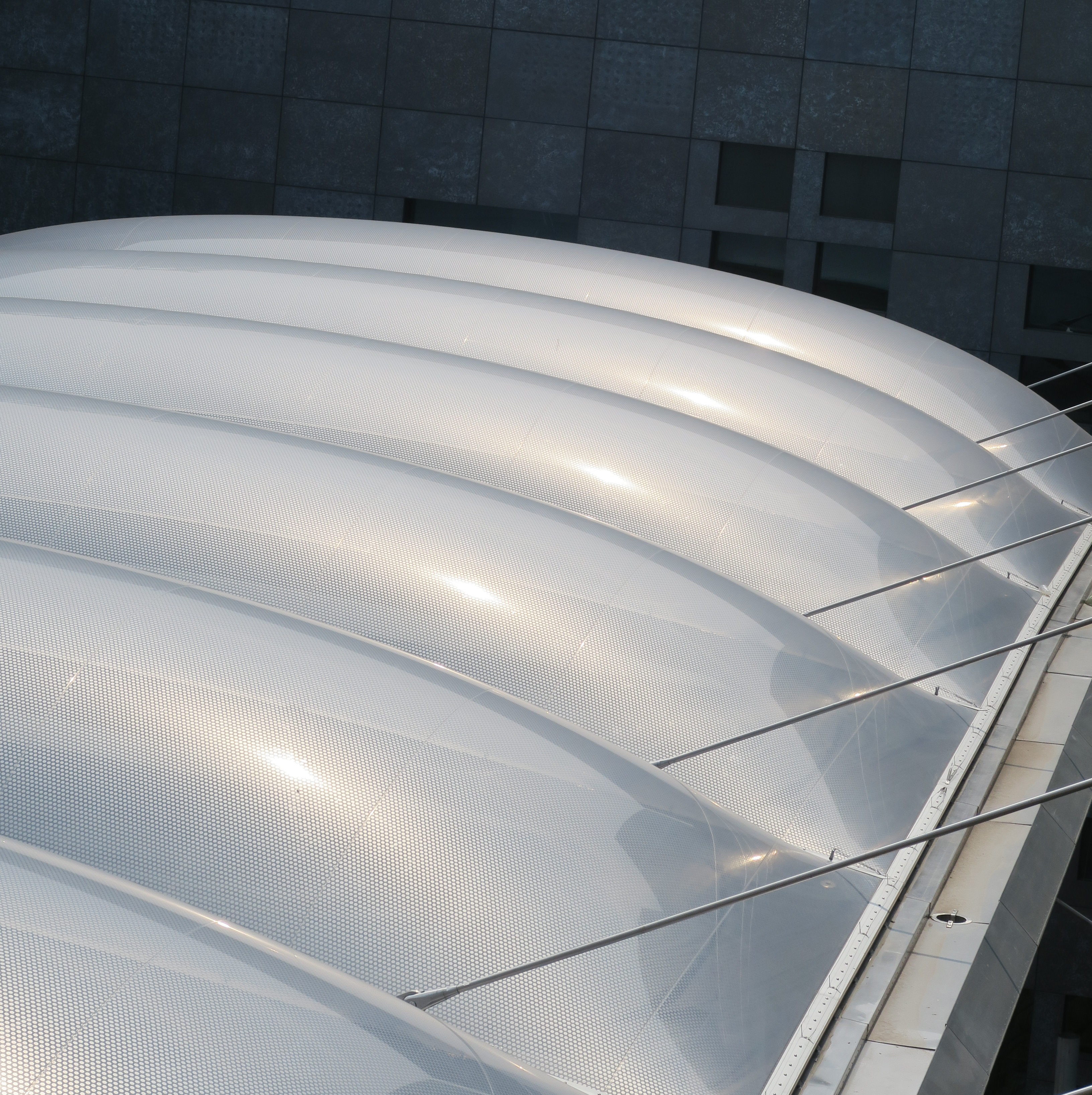

The project was part of a larger development to provide an official residence for Australia’s permanent mission to Indonesia. Our project scope was to provide the ETFE canopy which is suspended over the chancellery courtyard.

The canopy was designed as a shelter from the weather for people in the courtyard area. The canopy incorporates deep ETFE pneumatic cushions and stainless structural steel suspended 10 stories above a courtyard by tie rods.

The Embassy delivers Australian-based officers and their families’ accommodation and recreational facilities. It is Australia’s largest embassy complex in the world.

What was the purpose of this project? What did the client request?

The overall purpose of the canopy was to provide protection to the courtyard area. The canopy is supported by stainless steel tie rods that are fixed to the concrete substructure of the main chancellery buildings, creating a floating illusion.

The client had requested a canopy that could offer a complete protection solution for the courtyard below. Longevity and durability of the structure was also stressed, resulting in stainless structural steel, and long-lasting ETFE to protect from the elements.

What is unique or complex about the project?

This project provided a unique opportunity to work with parameters that we often do not see in our projects. This provided the occasional challenge and inspired the necessity of creative solutions.

The most complex element of the project was working with the stainless structural steel. This material can be difficult to work with, so we opted for a 100% trial assembly in the factory, prior to assembly. This particular steel is extremely difficult to modify, so it was crucial to ensure everything was perfect before the materials arrived on site. There was to be no drilling or holes to occur on site. The framing of the steel also had to be faultless as the tolerances of ETFE are unyielding.

Working with local contractors introduced language barriers during installation. Other project challenges included collaboration with the Indonesian Government, and customs issues with material and equipment delivery.

Since the canopy is suspended 10 stories above the courtyard, access equipment could not fit in the space for installation. This meant that the entire installation was completed by scaffold, which had to be built up to the correct height. The frame components were dropped into place from above using a crane tower.

The unique elements of the structure are a combination of the stainless structural steel, the use of ETFE foil and the ‘floating’ aspect of the entire canopy, using steel tie rods fixed to the surrounding buildings to suspend the structure.

What were the results of the project?

The end result was a strikingly unique canopy resembling a floating cloud above the courtyard. The structure meets the brief and design expectations, providing an aesthetic yet protective solution, which pleased the client. The structure is a successful project, and performs exactly as intended.

The courtyard below remains protected from the elements, yet has a space that allows plants and a natural environment to flourish, thanks to the innovative design of the ETFE canopy.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG