Company:

Cool Awnings (Jak's Awnings) Auckland,

Project Details

Fabric 1

Sundream

Producer:

Hiraoka & Co. Ltd.

Supplier:

Helioscreen Australia

Please describe the project specifications

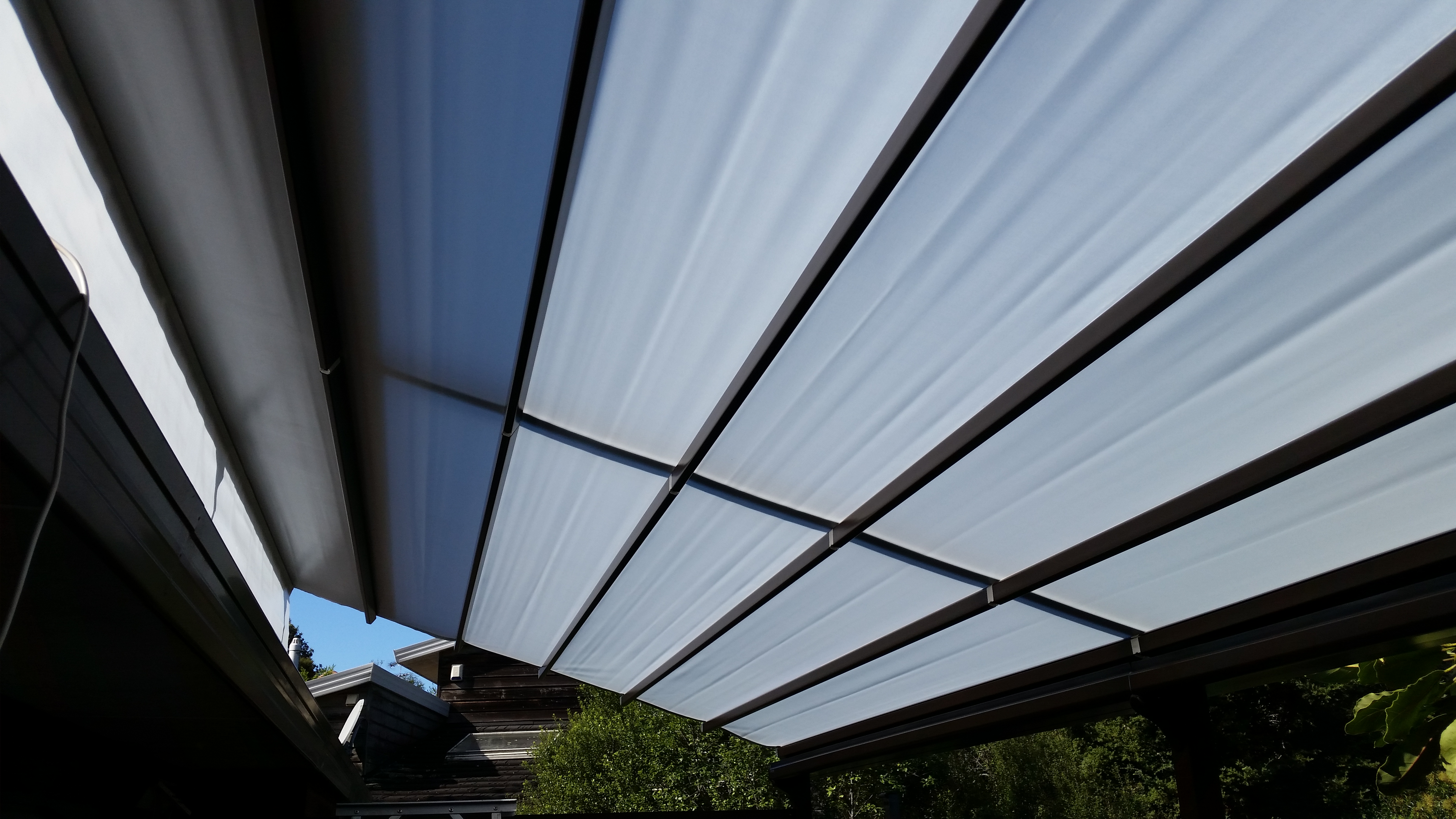

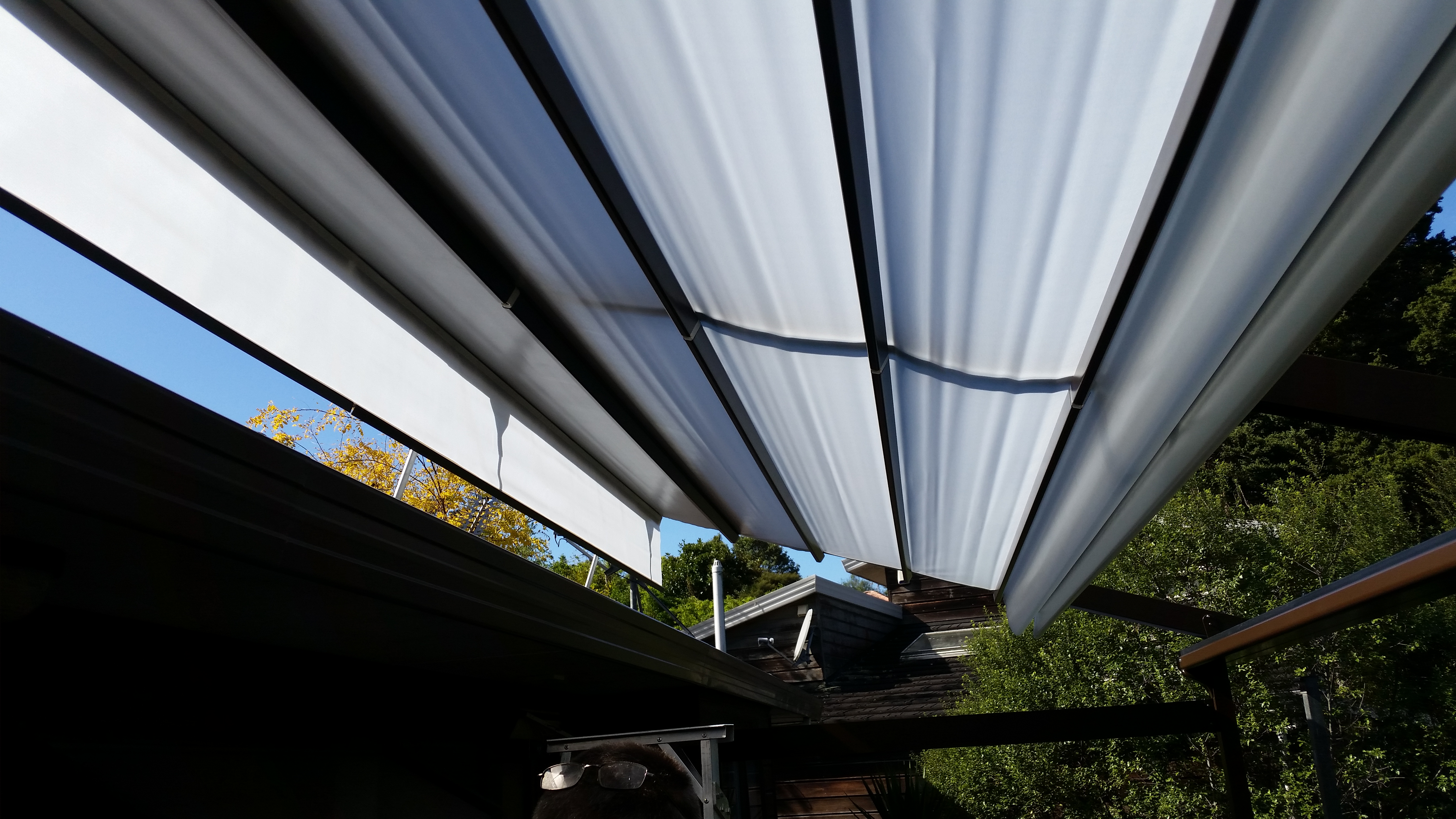

Project was a retractable roof system installed through the roof to cover a deck.

What was the purpose of this project? What did the client request?

The customers’ brief was to provide a waterproof shade covering a large deck that was also retractable.

What is unique or complex about the project?

Our answer was the Helioshade retractable roof system which is a motorised retractable shade using PVC fabric. This was the first time we did this product and it had to be complicated. No simple wall fixing here. We had no plans to work off and the deck we were going to cover didn't yet exist.

The deck was to undergo changes prior to installation and the site measure was on the understanding that the overall size would not change or impact on our post footings for the awning. The retractable roof system is ordered from an overseas supplier and has a longer lead time than usual so we had to order the system well before the new deck was going to be done to ensure that the retractable roof system would arrive in time to be installed once the new deck was ready. We worked on the assumption that the new deck would be the same dimensions as the old deck. As it transpired the new deck turned out to be a little smaller and the posts ended up landing on the top plate of the balustrade, which worked well and looked great. We had a number of challenges with the assembly of the unit which required some urgent lateral thinking but were all overcome onsite in a timely fashion.

Fixings were very difficult as we had to lift roof sheets to put fixing brackets into the roof framing and then nail it all back down while maintaining weather-tightness. The product that the customer wanted required a minimum 7 degree fall which they could not get attaching to their wall or soffit, so we needed to design the unit to go up and over their roof. To attach to the roof we had to design special brackets that went through the roof (which was decramastic long run type steel) which was removed on the awning side up to the ridgeline, and the ridgecap had to be removed (luckily there has been no leaks). The special brackets were engineered to tie into roof trusses and a small hole had to be cut into the roofing iron at the relevant points so the upright could fit down into the brackets, and then the hole was sealed using plumbing fittings.

What were the results of the project?

Customer was very happy with the retractable roof system and wanted the sides enclosed too. End result after we closed in the sides with static panels and drop curtains was a very satisfied customer and an awesome looking product.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG