Company:

Aussie Boat Covers (VIC) Pty Ltd Elwood, VIC

Project Details

Fabric 1

Sattler

Producer:

Sattler AG

Supplier:

HVG Australia

Fabric 2

Vinyl, clear

Producer:

O'Sullivan Films

Supplier:

NolanUDA

Fabric 3

Zip

Producer:

Paskal

Supplier:

Paskal Australia

Engineer Name 1

Neil Hancock

Engineer Company 1

Aussie Boat Covers

Design Name

Neil Hancock

Design Company

Aussie Boat Covers

Fabrication Name

Neil Hancock

Fabrication Company

Aussie Boat Covers

Project Manager Name

Neil Hancock

Project Manager Company

Aussie Boat Covers

Installation Name

Neil Hancock

Installation Company

Aussie Boat Covers

Please describe the project specifications

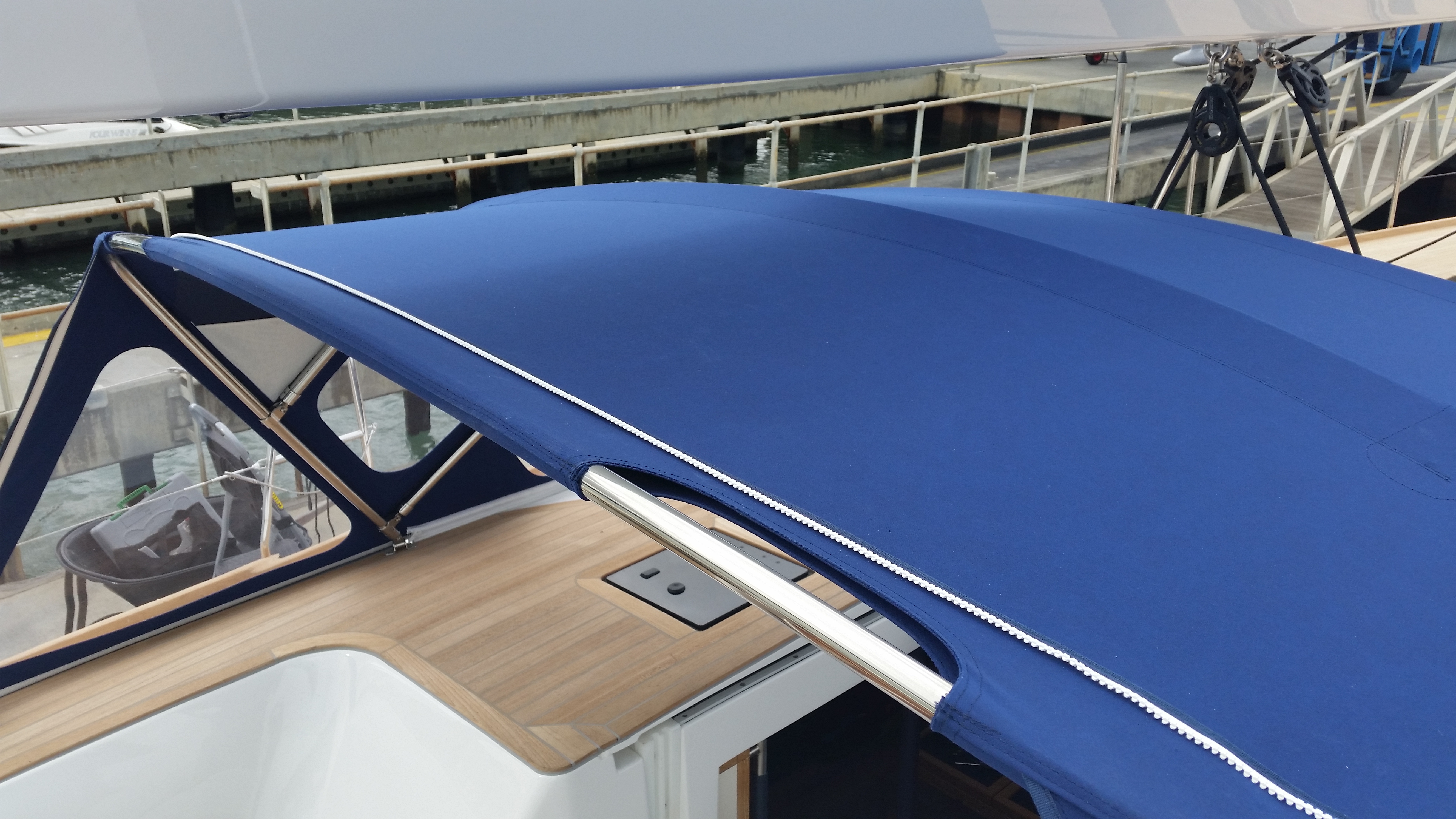

Bordeaux CNB 60 cockpit bimini top and spray dodger with connector using Sattler Marine Blue coated acrylic canvas, O'Sullivans 40 thou O'Sea polished clear and Paskal S Lock waterproof zips.

What was the purpose of this project? What did the client request?

The concept was to give as much cockpit sun coverage as possible to protect the teak decks while in the marina then make the covers functional for sailing and still have cover from the elements for the boat and it's passengers.

The client and his family are tall people and needed the covers to comfortably accommodate then with the express need for them to be strong and stable.

They also requested that all covers be easily removed for racing events and that the frames be stored on deck safely with covers to hide them in.

What is unique or complex about the project?

The complexity begun with the size of the steel required to accomodate the 15' cockpit beam and the positioning of the mast main stays. Inch and a quarter stainless steel tube and fittings with twin securing points allowed us to build a solid structure that will cope with ocean swells and unsteady sailors. The bimini frame , the bimini rear stay and the front pull down cables all attach to the existing pushpit, this needed lengthly consideration so as to not compromise the rail structure but also not to compromise cockpit movement to and from the helm.

The dodger frame needed to collapse when not in use into a bag then onto the deck in an innocuous place so as not to be protruding when collapsed and sailing. This was achieved by patterning the deck shape, building the frame to that shape then transitioning all those measurements into an aesthetically appealing, strong and functional structure.

The shear size of the connector was addressed by laminating 11 metres of fabric for stability then manufacturing it with consideration to load points that didn't compromise the bimini and dodger covers.

What were the results of the project?

Sailability with bimini and dodger in place is by far the best appreciation of results. This vessel has sailed many ocean miles in foul weather with great success. It has also won many class races with covers off. The most rewarding part to follow both of those situations is the ability number one that the structure and fabric is not compromised in harsh conditions and number two that the client is able to remove and refit covers and frames without any difficulty and the integrity of the design continues to show off the boat.

One of our main considerations when designing frames and covers is that they be used as holding points when sailing. It is a major consideration and we always let our clients know that these frames can be hung of or tethered to for safe movement in and around the vessel. The result of that detail has helped us achieve amazing results in further developing our techniques in design and manufacture.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG