Company:

TenCate Geosynthetics Americas Pendergrass, GA

Project Details

Fabric 1

Miragrid

Producer:

TenCate Geosynthetics Asia

Fabric 2

OTHER

Producer:

TenCate Geosynthetics Asia

Project Manager Company

National Solid Waste Management Department

Please describe the project specifications

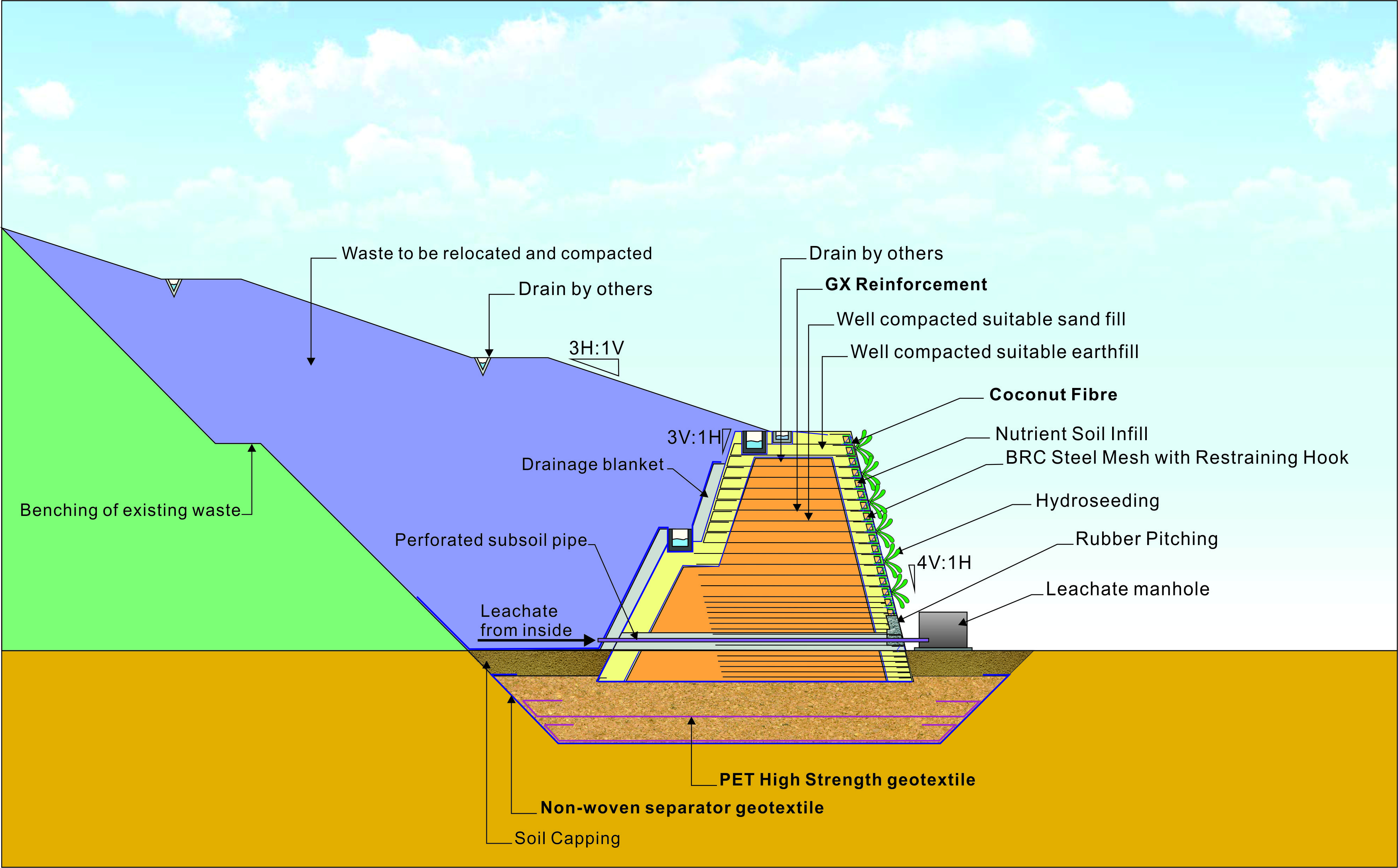

The project involved the construction of a reinforced soil wall with vegetation facing by using geogrids as an alternative solution for the landfill capping. This method was used to replace the traditional and conventional method to build the gentle slope capping to maximize the municipal solid waste dump. Length of wall = 400m, Total Max. Height = 11.5m including 1.5m embedded depth

What was the purpose of this project? What did the client request?

As the world hurtles toward its urban future, the amount of municipal solid waste (MSW), one of the most important byproducts of an urban lifestyle, is growing even faster than the rate of urbanization. Due to scarcity of land available and the increase of land price, the authority decides to maximize the use of the land to contain the solid waste. The idea of a reinforced soil structure using reinforcement geogrids-geotextiles came into the picture and provided the most economical, and best technical, solution whereby a steep 4V:1H was built up to a maximum 11.5m height with vegetation facing. This reinforced soil structure system which provides environmental sustainability and aligns with the company’s vision and mission to reduce the negative impact on the environment.

What is unique or complex about the project?

Sandy soil was used as the reinforced fill material and Miragrid® GX geogrids composed of high modulus, high strength polyester yarns coated with a robust polymer was selected as the reinforcement. While providing excellent strength, extension and durability properties ensure the design life of the structure especially for the landfill project site which contains high volume of leechate. Pre-fabricated BRC steel basket was used to facilitate and form the reinforced soil wall geometry. Some suitable fill was placed on the front slope face in order for the vegetative growth. The biodegradable erosion protection mats Polyfelt® Envirofelt CF was installed at the slope surface to maintain the moisture and trap the grass seed to expedite the slope vegetation.

What were the results of the project?

The client is satisfied with the reinforced steep slope system as it fulfils their policy and aims to provide a comprehensive, integrated, cost-effective, and sustainable solid waste management system in line with society's demand for environmental conservation and public well-being.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG