Company:

University of Minnesota Saint Paul, MN

Project Details

Fabric 1

8 mil Actuator Wire

Producer:

Flexinol (r)

Supplier:

Dynalloy, Inc.

Fabric 2

Tex 60 Aramid Fiber Yarn

Producer:

Kevlar (r)

Supplier:

DuPont (TM)

Fabric 3

Heating Fabric

Producer:

UltraHeating Fabric with MicroMetal Conductive (MMC) Yarn

Supplier:

WireKinetics Co., Ltd.

Engineer Name 1

Rachael Granberry

Engineer Company 1

University of Minnesota

Design Name

Julianna Abel

Design Company

University of Minnesota

Architect Name

Brad Holschuh

Architect Company

University of Minnesota

Please describe the project specifications

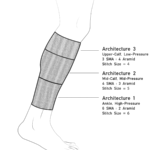

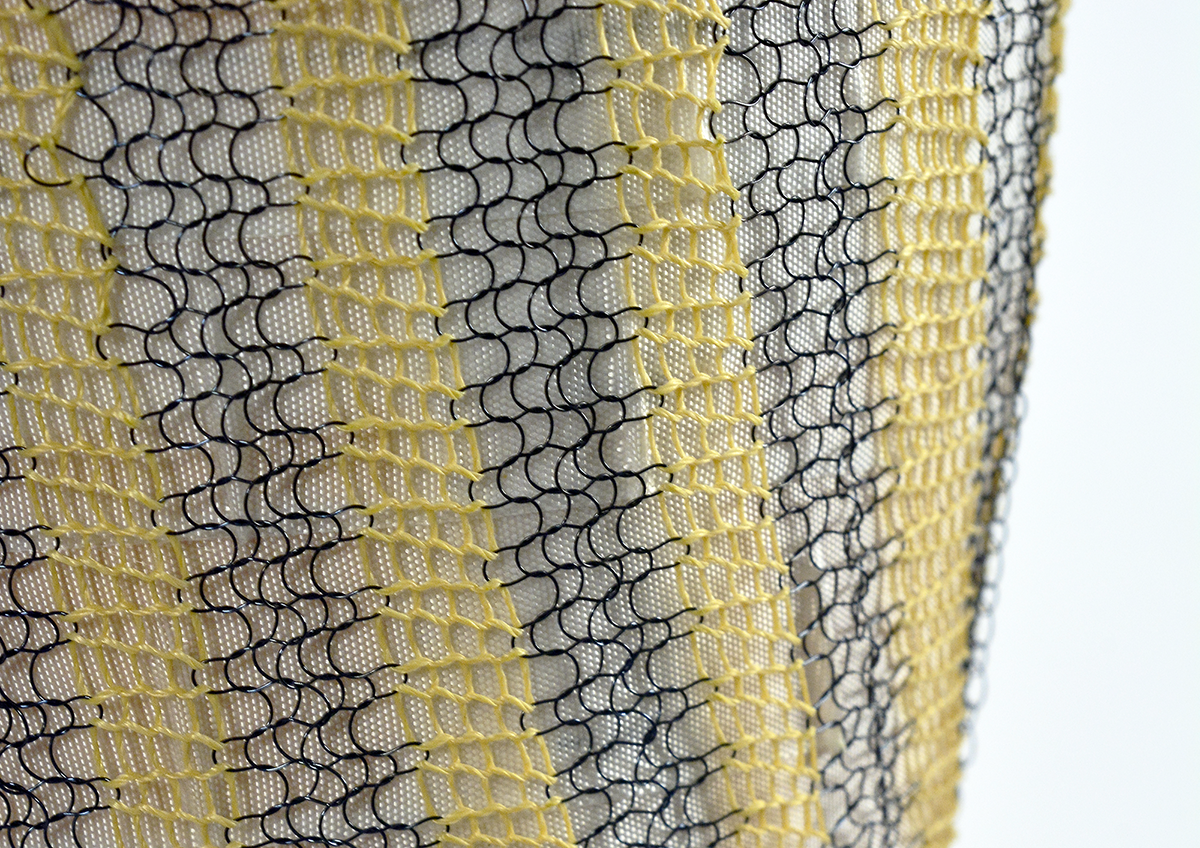

Active Knit Compression Stockings offer a new, market alternative to under-sized elastic and inflatable compression technologies by leveraging recent advancements to smart material design. Shape memory alloys (SMA) are a type of smart material with shape recovery abilities that can be designed (through an annealing process) to return to a remembered form when heated. In the case of Active Knit Compression Stockings, SMA wires (i.e. Flexinol® Actuator Wire) are trained to remember a straight form. When incorporated into a looped-yarn, knitted fabric (via machine or hand knitting) heated SMA wires straighten, producing a large deformation across the fabric surface. Active Knit Compression Stockings are designed using SMA wires in a stockinette or garter stitch knit pattern and the deformation is a width-wise contraction that produces body compression.

The prototype is designed to apply gradient and pulsing pressures to the lower leg (i.e. tighter at the ankle, looser at the knee) by modifying the fabric architecture and intensity of stimuli across the lengths of the garment. Specific functional design techniques to produce such an effect include modification of knit stitch size, number of non-SMA yarns included in the knit structure (i.e. Kevlar® aramid yarns), and temperature to which regions of the SMA knit garment is exposed. The prototype dimensions are 26 cm tall by approximately 16 cm in width and depth. The prototype was knitted with a Passap E6000 double bed electronic weft knitting machine using SMA wire (Flexinol® Actuator Wire, 8 mil, Dynalloy, Inc.) and passive yarn (Kevlar® aramid fiber yarn, Tex 60, DuPont™). For display purposes, the Active Knit Compression Stocking is combined with an UltraHeating Fabric sleeve with incorporated MicroMetal Conductive (MMC) yarns designed by WireKinetics Co., Ltd. to demonstrate prototype functionality. The heated sleeve is partitioned into three, independently controllable cuffs (i.e. ankle, mid-calf, upper-calf) to provide independently controllable thermal regions. This allows the garment to transmit pulsing as well as gradient pressures to the body (two mechanical techniques for therapeutic fluid manipulation), starting at the ankle and working up to the knee. Additionally, the prototype can be turned "on" and "off," allowing for easy donning. Through engineered knit design and localized temperature control, Active Knit Compression Stockings deliver complex, medically therapeutic pressure to the body in a low-profile, discrete form factor.

What was the purpose of this project? What did the client request?

On-body, mechanical compression therapy is used to treat a wide variety of medical disorders, including lymphedema, orthostatic intolerance, postural orthostatic tachycardia syndrome (POTS), deep vein thrombosis (DVT), varicose veins, and a variety of anxiety-related disorders. Current wearable compression technologies include inflatable garments that are large and tethered to an inflation source and passive, elastic stockings that are difficult to don/doff and do not apply controllable or dynamic pressures on the body. Inflatable compression garment designers have attempted to make pneumatic sleeves more mobile by introducing portable inflation sources; however, this solution increases garment weight and garment form factor, making it unrealistic for everyday use. Devices have been designed to make donning elastic compression stockings easier for older adults with limited dexterity and upper body strength; however, there are currently no methods to control or modify pressures exerted by stretch-yarn compression garments on the body. Active Knit Compression Stockings offer the novel possibility to combine the low-profile, mobile qualities of stretch-yarn compression stockings with the controllable and dynamic features of inflatable sleeves.

What is unique or complex about the project?

Active Knit Compression Stocking prototypes designed for the lower leg introduces a new method of on-body use for shape memory alloy (SMA) knit architectures. Currently, there are no other compression technologies that are capable of providing dynamic pressures to the body in a low-profile, mobile form factor. Active Knit Compression Stockings have the future potential to modify pressure output, actuation speed, and pulsing patterns in response to changes in the wearer’s dynamic physiology and medical needs. Because human bodies are constantly changing in dimension as well as physiology, advanced medical compression garments will require dynamic responses to effectively manage a patient’s condition.

What were the results of the project?

While our Active Knit Compression Stocking satisfies proof-of-concept requirements, the temperature required to active the garment (70ºC/159ºF) is not appropriate for on-body use. Future Active Knit Compression Stockings could be designed using SMA materials that contract when the garment touches the skin (37ºC/98.6ºF). Alternatively, Active Knit Compression Stockings could be activated by electrically heating SMA materials at a lower temperature with a small battery pack if properly insulated. Continued research will be conducted to improve and optimize the design to enhance/refine functional performance and wearability.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG