Company:

Mid-Mountain Materials Inc Mercer Island, WA

Project Details

Fabric 1

OTHER

Producer:

OTHER

Supplier:

OTHER

Engineer Name 1

Amulya Das

Engineer Company 1

Mid-Mountain Materials, Inc.

Design Name

Supersonic Inflatable Aerodynamic Decelerator

Design Company

NASA Jet Propulsion Laboratory

Architect Name

John R. Knapp

Architect Company

Mid-Mountain Materials, Inc.

Fabrication Name

N/A

Fabrication Company

AIrborne Systems and NASA Jet Propulsion Laboratory

Subcontractor Name

N/A

Subcontractor Company

Airborne Systems and NASA Jet Propulsion Laboratory

Graphics Name

N/A

Project Manager Name

Amulya Das

Project Manager Company

Mid-Mountain Materials, Inc.

Installation Name

N/A

Installation Company

NASA Jet Propulsion Laboratory

Please describe the project specifications

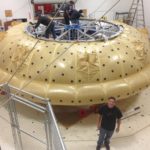

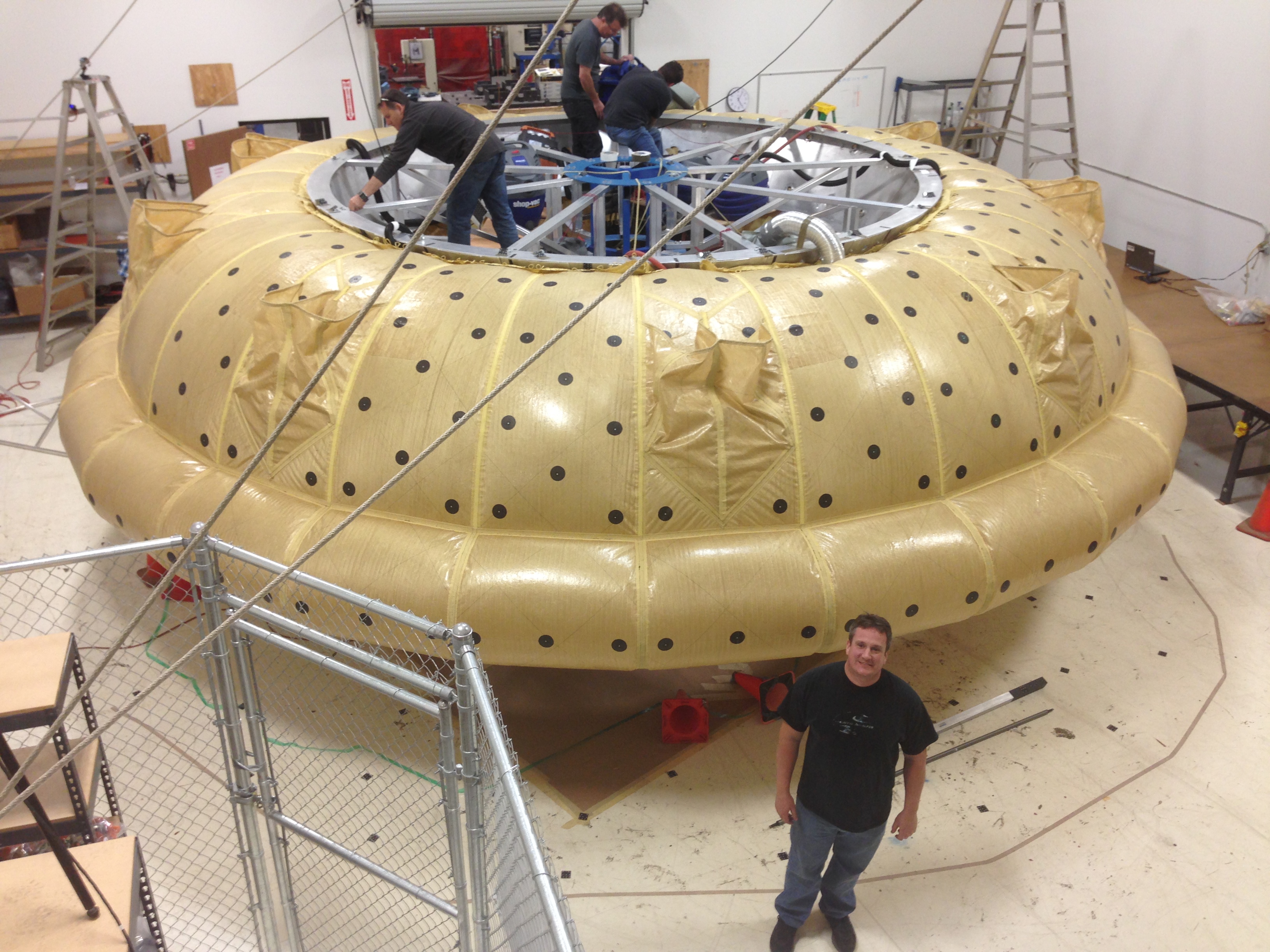

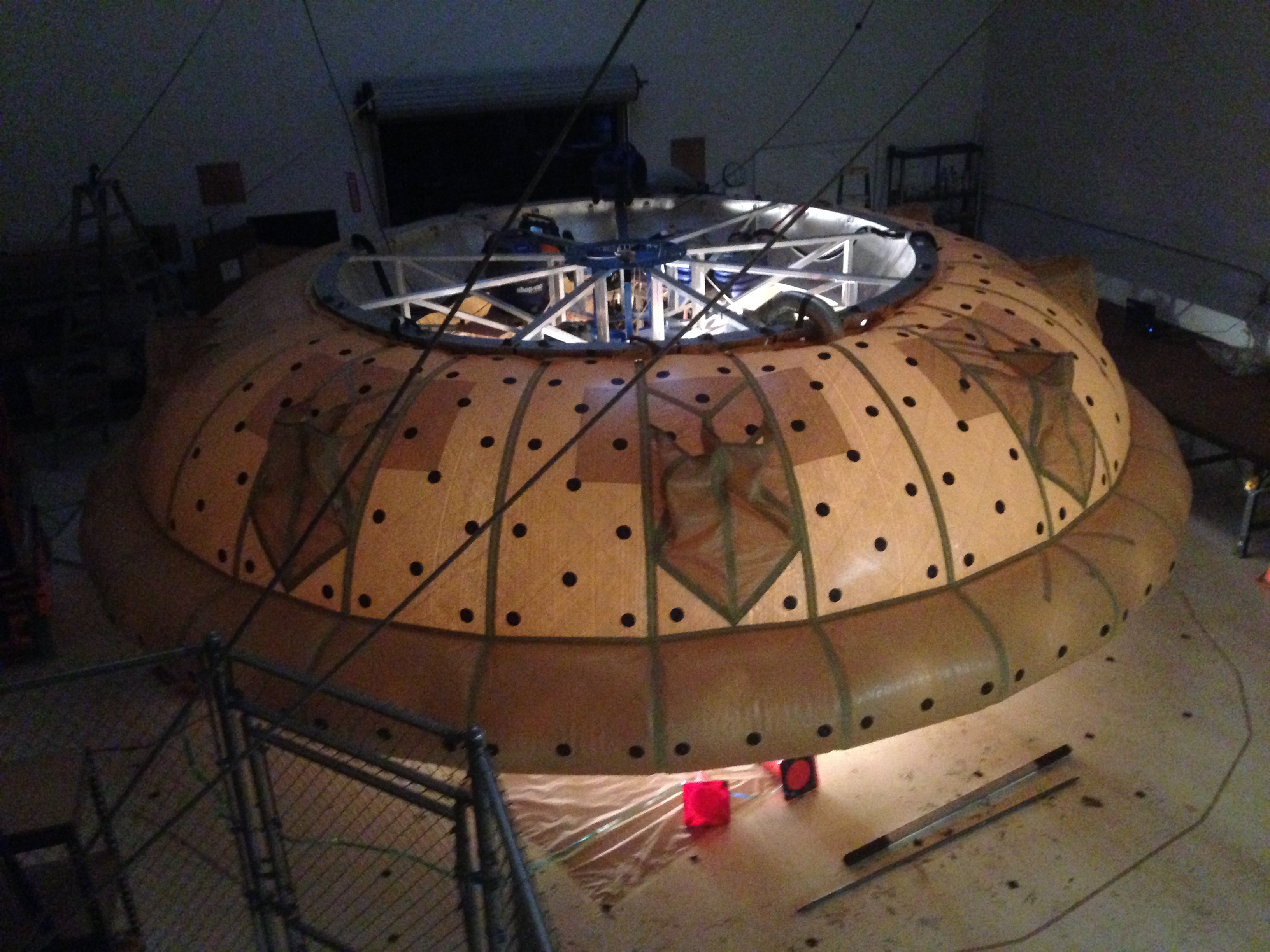

Mid-Mountain Materials, Inc. engineered and manufactured a very high-temperature resistant coated fabric for use as a Supersonic Inflatable Aerodynamic Decelerator (SIAD-E) on the Mars 2020 Lander.

What was the purpose of this project? What did the client request?

The purpose of this project was to engineer a coated fabric that would be used as an interplanetary decelerator to slow down the Mars 2020 Lander from a speed of 5000 MPH to 200 MPH. Decelerating the lander would allow a parachute to deploy, further slowing the lander to a set altitude over Mars surface where rockets suspend the lander and its frame and the lander is lowered to the surface on cables by a “Sky Crane”, which would ensure a safer landing on the Mars surface.

A NASA engineer called Mid-Mountain Materials, Inc. requesting a fabric that could withstand temperatures to 5000°C (9032°F) at Mach 8, (6136 MPH), for a maximum of 20 seconds. The engineer further explained the fabric would be fabricated into a ballute (ballon/parachute) in an iso-tensoidal structure in order to share forces in all directions.

What is unique or complex about the project?

The very high temperatures combined with the speed at which the Supersonic Inflatable Aerodynamic Decelerator would deploy made this a very unique application. A fabric with a very high tensile strength had to be combine with an ablative silicone rubber that would sacrifice itself and protect the base fabric for a short duration.

What were the results of the project?

As the mission is not until 2020, we do not have actual results right now. The initial testing of ARMATEX® Spacetex yielded very positive results. The first production run was fabricated into the Ballute at JPL and was tested on a rocket sled. Temperature and speed data points were recorded. The second production run went on a high altitude balloon that launched a rocket with its payload on it high into our atmosphere. The ballute was deployed, inflated, and performed its intended function of slowing. Both the speed and temperature were higher, and again data was collected. The NASA/JPL engineers took the data sets and extrapolated them out to mission speed and temperatures, and concluded it would be able to perform as required with a safety margin. We look forward to the Mars 2020 Lander launch with great anticipation.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG