Company:

Eventstar Structures Medley, FL

Project Details

Fabric 1

Vinyl

Producer:

Serge Ferrari North America Inc.

Supplier:

Serge Ferrari North America Inc.

Fabric 2

Vinyl

Producer:

Naizil Coated Fabrics Inc.

Supplier:

Naizil Coated Fabrics Inc.

Fabric 3

Webbing

Producer:

GSL

Supplier:

GSL

Engineer Company 1

Eventstar Structures, Corp

Design Company

Eventstar Structures, Corp

Architect Company

Eventstar Structures, Corp

Fabrication Company

Eventstar Structures, Corp

Subcontractor Company

Eventstar Structures, Corp

Graphics Company

Eventstar Structures, Corp

Project Manager Company

Eventstar Structures, Corp

Installation Company

Eventstar Structures, Corp

Please describe the project specifications

The Cosmopolitan Pool Deck Structure was a custom temporary structure built and installed on the pool deck patio of the Cosmopolitan Resort on The Las Vegas Strip. The structure covered the primary pool and event area, and created a climate controlled space for the 5 month Vegas winter season.

Our client’s primary goal was to transform this roof deck space that would ordinarily be completely deserted during the winter into a winter party space that attracted the biggest named DJs and hordes of guests. The client also required a significantly expedited install timeline to comply with street shutdown restrictions enforced by The City of Las Vegas.

What was the purpose of this project? What did the client request?

Our client wanted to utilize their pool day club year round instead of accepting the usual Las Vegas winter hiatus. They tasked us with designing, manufacturing, engineering and installing a structure that not only provided a climate controlled event space, but that also transitioned seamlessly with the interior of their club and other amenities during the winter season of Las Vegas.

The pool deck structure also needed to support the rigging of production elements as well as support a robust fire safety system. These elements needed to be preassembled on the street level before they could be raised to the roof deck. The client also wanted the roofing panels to be transparent to help maintain as close to an “open air” feel as possible in the enclosed structure and allowing guests to be able to see the sun during day club hours.

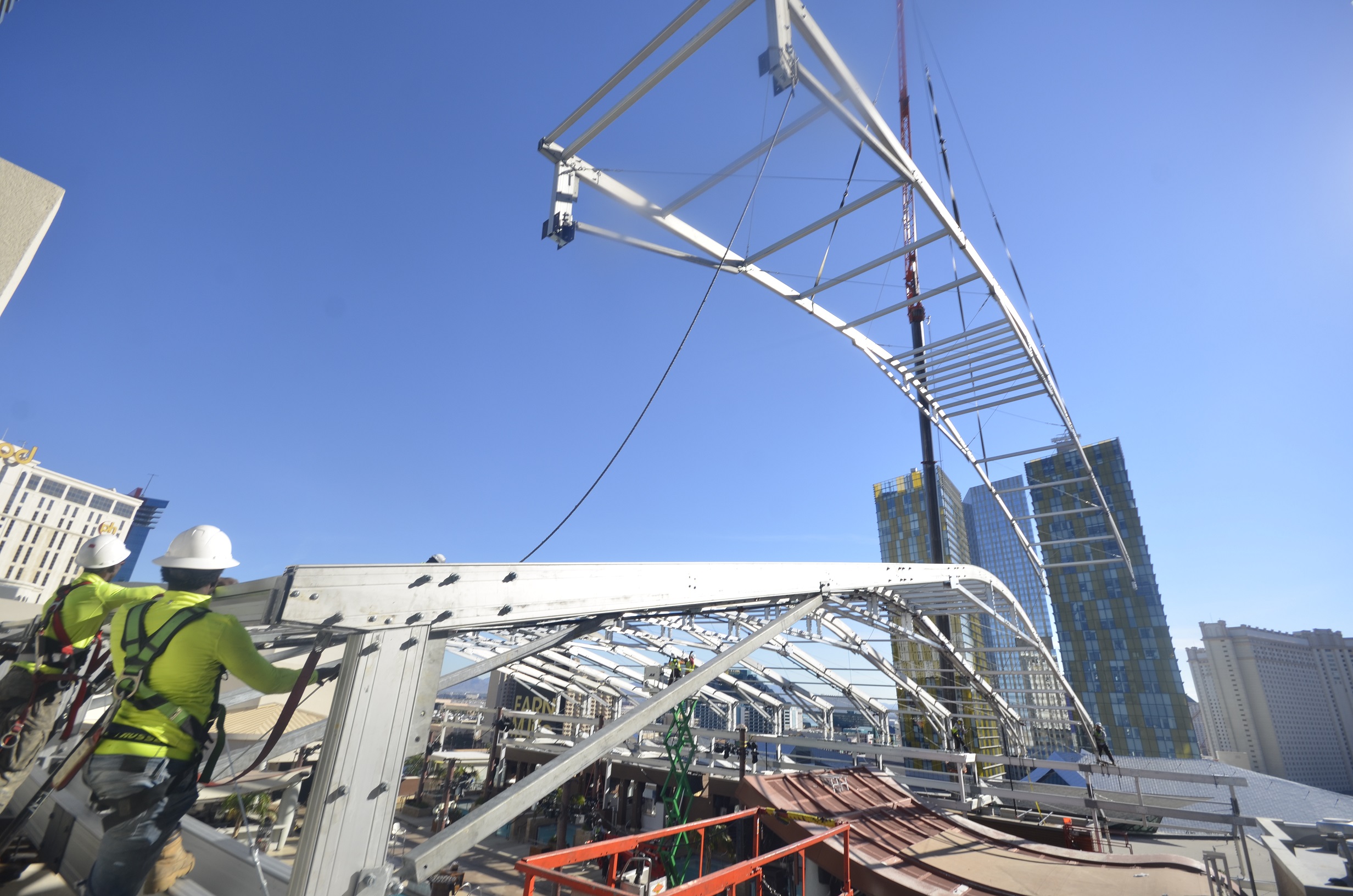

The 20,000 sq. ft. structure was manufactured and installed one the 12th story terrace of The Cosmopolitan hotel after a significant amount of design, engineering and logistical planning.

What is unique or complex about the project?

The timeframe from initial discussions with the client to installation of the structure was less than two months. Given the complexity of this structure and the project location, that limited timeframe created significant challenges throughout the entire process.

Numerous site inspections were conducted and multiple design revisions were done in order to get to a concept that was both aesthetically satisfactory to the client, as well structurally sound. A curved roofing design was used to give a sleek look to the structure while also having an aerodynamic function to minimize the live loading on the roof’s structural members. This load minimization was essential given the substantial winds that can occur in The Mojave Desert and surrounding areas. Clear roofing panels were reinforced to increase their durability during the 5 months the structure would be erected. Structural member splices and gusset connections were also reinforced to not only handle the typical site specific load requirements, but to also support the production and fire safety rigs.

Because the roof deck had a minimal load capacity, the typical heavy equipment that would be used for this type of install were not available. The majority of the structural components had to be put together on street level and craned up to the deck individually. The fire safety components were attached to the structural members and tested prior to be the roofing components being lifted. This required a choreographed build that minimized the crane down time, and ultimately cost. After the build of components were completely, they were raised to the pool deck level. A team of riggers completed component connections to the main framing before the crane could release its load. These crane picks had to be repeated over 20 times until all of the main components were located and properly “safed” on the deck.

Installing the cladding proved extremely challenging as well. The equipment that we were able to use could not access all locations on the deck due to pools and cabanas that took up a significant square footage of the space. Special motors were used to help drive the keder fed vinyl panels through the tracks, and riggers were meticulous in feeding the panels as to avoid snags. If the vinyl got stuck while being fed through the tracks, the entire panel would have had to be removed.

Many complications were encountered during the build, including some unforeseen delays. This was particularly challenging as build times were limited due to events taking place at the venue in between build milestones. A team of engineers and architects were on site during the entire build to help manage some of the structural complications that arose to minimize the delays these would cause.

What were the results of the project?

The Cosmopolitan Day Club Structure was completely installed in time for the winter season. Our client was ecstatic with the end product and their ability to maintain summer like temperatures at the venue in the cold of a Las Vegas winter. Months of events were held at the Pool Deck Venue, and tens of thousands of guests experienced the client’s goal of a summer in winter.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG