Company:

Baytex

Project Details

Fabric 1

Precontraint 802 Formula S2 opaque

Producer:

Serge Ferrari Lyon France

Supplier:

Innova International

Engineer Name 1

David Barnard

Engineer Company 1

REDCO NZ Ltd

Design Name

Andrew Lingman

Design Company

Baytex

Architect Name

Julian Tankard

Architect Company

Baytex

Fabrication Name

Katie Duncan

Fabrication Company

Baytex

Project Manager Name

Julian Tankard

Project Manager Company

Baytex

Installation Name

Andrew Lingman

Installation Company

Baytex

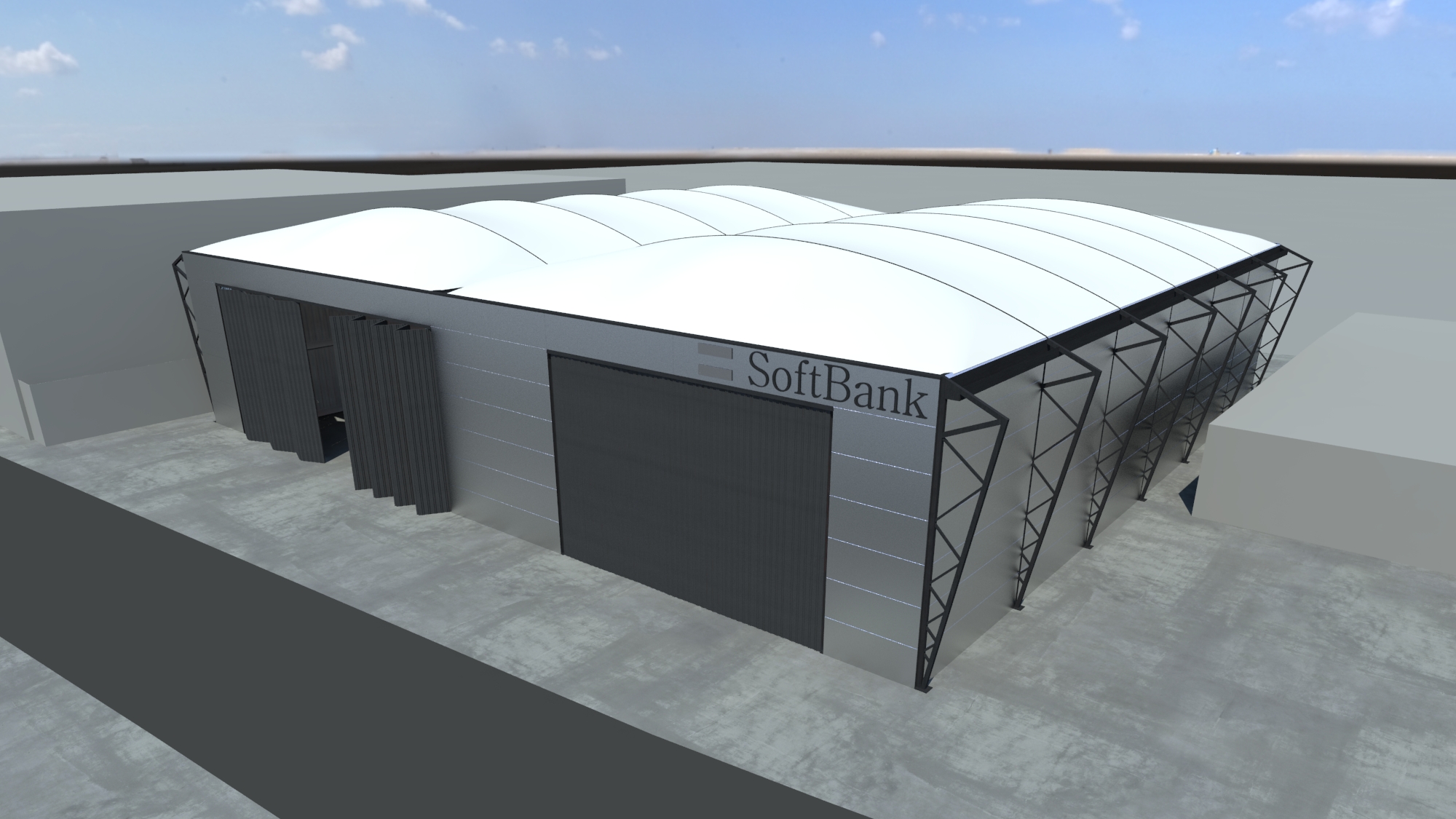

Please describe the project specifications

To produce a 33mx30m Arched Truss building 7m high with 2 separate working areas. The fabric building had to be fully transportable and be packed into 4 shipping containers and reinstalled at the next location, very helpful for a sailing team with a world-wide itinerary! The tent had the ability to hoist the catamaran or wing sail high into the 7m roof space with the 4-tonne chain hoist, as supported by the tent’s framework.

What was the purpose of this project? What did the client request?

The purpose of this job was to provide 2 separate workshop spaces, to house a high-performance catamaran and its aerofoil wing-sail, which was both re-locatable and able to stand up to the rigid building regulations of the island nation where the tent would primarily reside. Each space has custom built container workshop for work on the different parts of the catamaran. Key words from the Design Brief were ‘Clean’ and ‘Contemporary’.

What is unique or complex about the project?

There were a number of complexities to this project with the main ones being around the timelines, logistics and budget of the project. With regards to the timeline, the entire project needed to be completed within 5 months. This left us a 3 month engineer / design / manufacture ‘window’, one month to ship the product over the other side of the world and then one more month to complete the installation, a pretty tight schedule for fully engineered, high-spec 1000+m2 structure! Logistically, because the location was over the other side of the world, our planning and accuracy had to be really ‘on-point’. It also meant that things like Work Visas had to be processed and local labour crews had to be organised and managed. Another big logistical challenge for this project was meeting the engineering requirements of the local authority (this tent is engineered to 153 mph – Category 3 Cyclone level!).

What were the results of the project?

The team, together with a crowd of over 500 dignitaries, friends, and family members, celebrated the completion of the team’s new base on Saturday, May 14 with a traditional “roof wetting ceremony”. The official opening of the facility caps a 5-month construction program and marks a significant milestone in the team’s campaign. “Unbelievable! I am really proud of our team”, said Team Premier, enthused by the progress the team has made since announcing their intentions just over one year ago.

Baytex continues to work closely with a number of professional sailing syndicates around the world. We were very happy to hear that our reputation as a quality supplier to this industry had found us on the Preferred Supplier List for a new team looking to make their mark!

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG