Company:

Covertex Membranes (Shanghai) Co. Ltd. Shanghai,

Project Details

Fabric 1

Précontraint 1202 Formula S

Producer:

Ferrari S.A.

Supplier:

Ferrari S.A.

Architect Company

Burns & McDonnell,Inc

Fabrication Company

covertex membranes (Shanghai) Co.,Ltd.

Project Manager Company

Time Qatar

Installation Name

Nobert Shimitz

Installation Company

PFEIFER Seil- und Hebetechnik GmbH

Please describe the project specifications

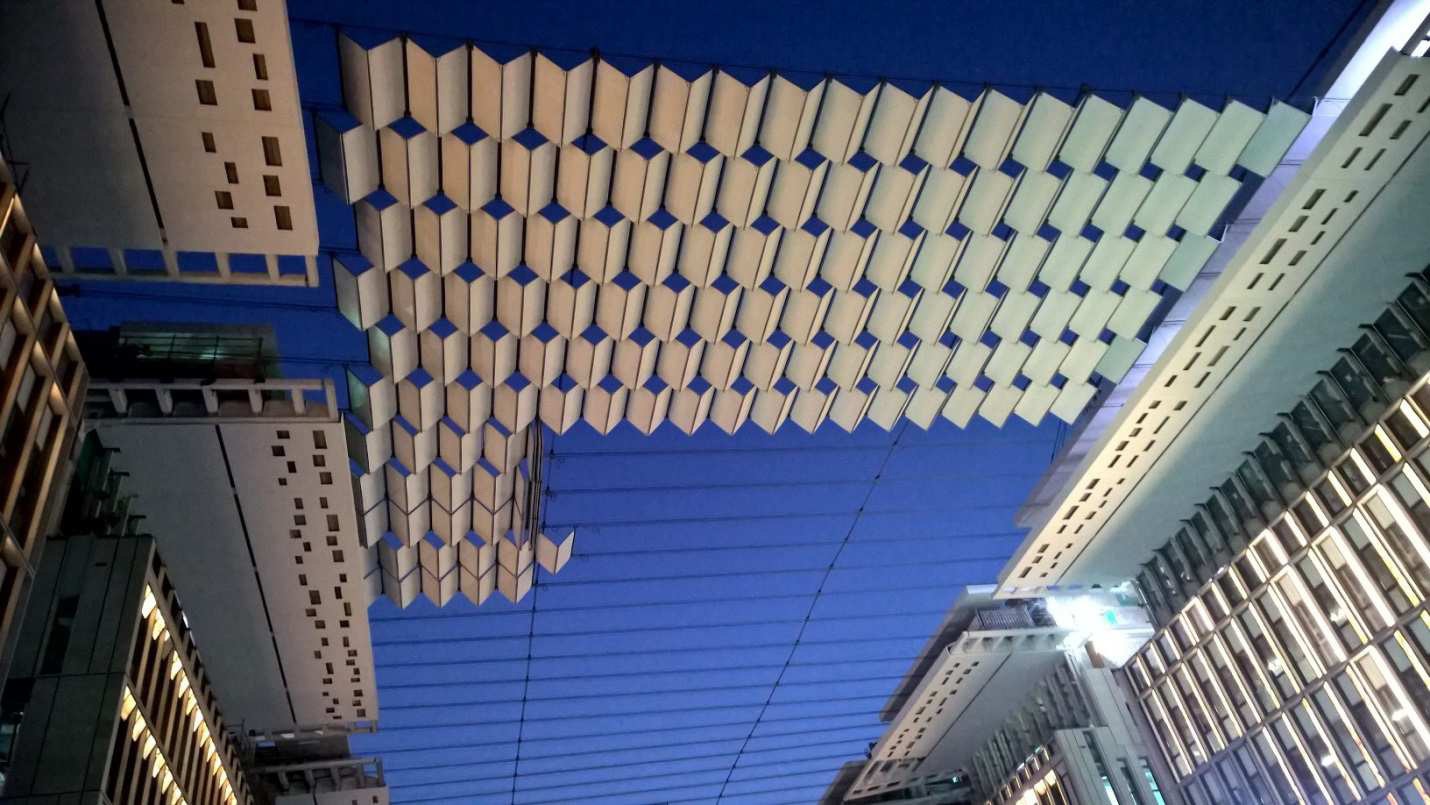

Barahat Al Nouq is the central square of the heart of Doha, capital of Qatar. Following traditional Arabic architecture, the new roof construction is reinterpreting ancient building elements which already functioned adaptive and responding. This is also the case with the new retractable roof with its movable membrane covered shading panels.

Barahat Al Nouq central square is the main public space of this development and is designed as an urban room functioning as a multi-purpose meeting space that comprises nine mixed-use, residential, commercial and retail buildings surrounding a major public square at the heart of the Msheireb.

What was the purpose of this project? What did the client request?

In Doha, daytime temperatures easily rise to 50°C. The concept of retractable shade canopy is to limit temperatures to below 32°C. The client expect that people can enjoy the perimeter restaurants and cafes. Natural light could be filtered to reduce solar transmission and to allow significant cooling.

What is unique or complex about the project?

The primary construction of the membrane panels is made up of four aluminum profiles. The upper, horizontal frame profile and both vertical ones can be bolted together. The lower horizontal beam is a sliding element which is inserted between vertical ones from below. This way the membrane can be inserted and then tensioned easily.

Upper and lower membrane panels were fabricated by our fabrication plant in Shanghai. The panels were pre-assembled with keder profiles on all of the edges so that they could be clipped into the main frame profile. Afterwards, the lower horizontal beam was screwed down into its final position. In this way pre-tension is introduced into the membrane panels and the flat membrane surfaces are stretched nicely and wrinkle-free. The final step of the panel assembly was the fixing of corner reinforcement plates, an outer edge cover and the panel hinges for suspension.

What were the results of the project?

The result of our work is a roof that incorporates adjustable and movable technology that can adapt to variations in climate and to the position of the sun. Membrane structures benefit from this trend because fabric and foil provides excellent material properties that

match the needs of kinetic systems; lightness, flexibility and adaptiveness.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG