Company:

TenCate Geosynthetics Americas Pendergrass, GA

Project Details

Fabric 1

Mirafi

Producer:

TenCate Geosynthetics

Supplier:

TenCate Geosynthetics Asia

Fabric 2

Polyfelt PEC

Producer:

TenCate Geosynthetics Asia

Supplier:

TenCate Geosynthetics Asia

Fabric 3

OTHER

Producer:

TenCate Geosynthetics Asia

Supplier:

TenCate Geosynthetics Asia

Please describe the project specifications

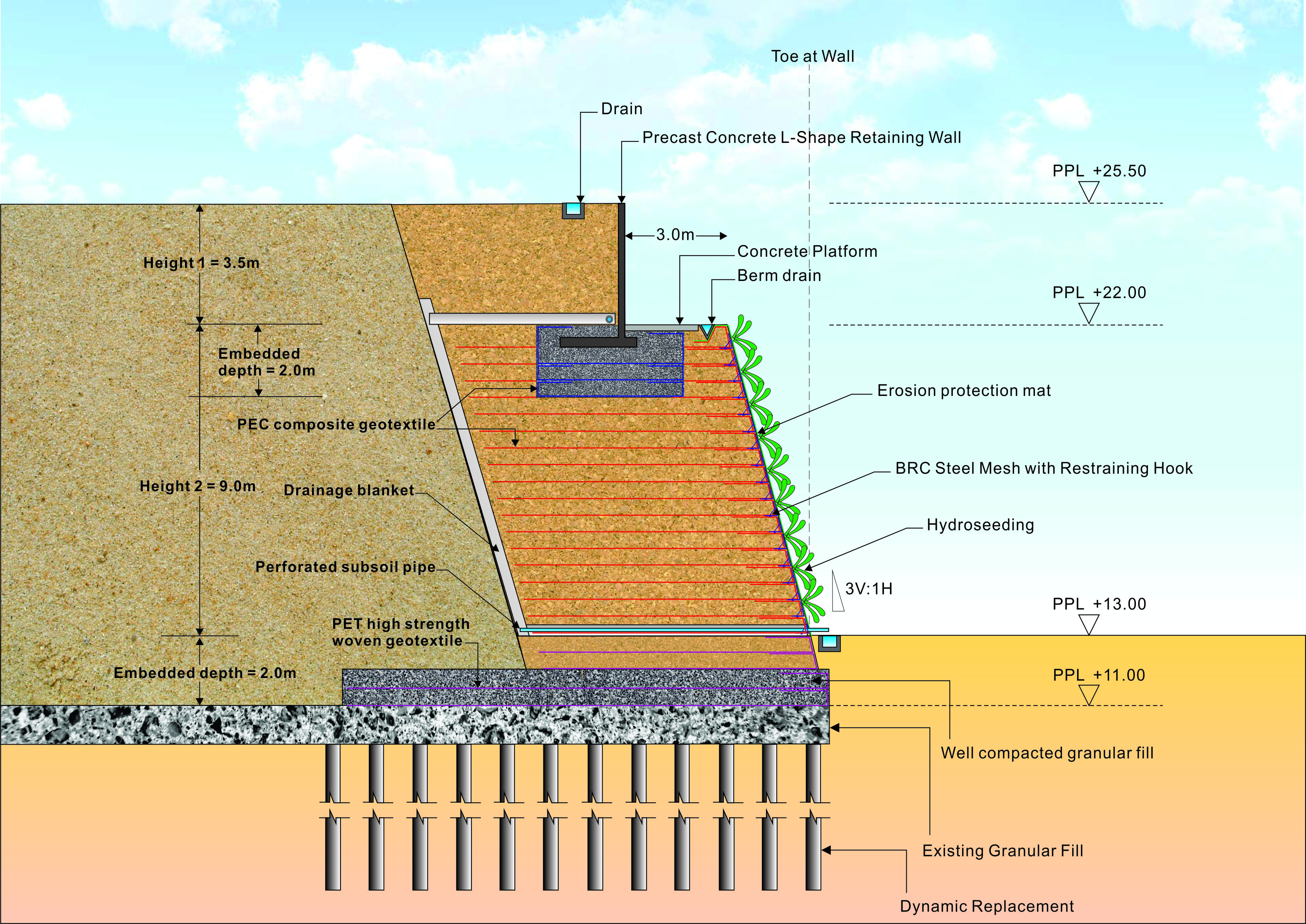

This project involved the redevelopment of a previous aircraft maintenance depot into a new airbase. To maximize the effectiveness of the land usage and create a flat site large enough for the apron and taxiway, 200m long and 14.5m high geotextile reinforced green wall was constructed for a platform extension.

Length of steep slope = 200m, Total Max. Height = 14.5m including 2m embedded depth

Mirafi® PET high strength woven geotextile, Polyfelt® PEC composite high strength geotextile, Polyfelt® Envirofelt CF erosion protection mats were the products used.

What was the purpose of this project? What did the client request?

A retaining wall was to be constructed at the lowest ground elevation level with some foundation improvement works that had been implemented within the area. It was anticipated that some settlement would occur during the construction of the retaining wall. A valuable solution was found by using a geotextile reinforced green wall system given that the structure is relatively flexible. It enabled settlement of the fill during the wall construction without creating undue deformations of the wall face. In addition, a 15m length with 3m wide of the spectator stage was proposed in the middle of the upper tier slope. Therefore, a 3.5m vertically faced structure formed using precast concrete L-Shape panel as facing was incorporated into the system. The green wall met the client’s demand for an environmentally and aesthetically pleasing engineered retaining wall.

What is unique or complex about the project?

The onsite material had to be used as backfill to minimize the need for importation of fill material. The area is subject to frequent rainfall for most parts of the year. The onsite material is not self-draining and the use of Polyfelt® PEC geotextiles with in-plane drainage capability allowed the use of the onsite material as backfill to construct the reinforced soil retaining wall. The surface was covered with Polyfelt® Envirofelt CF erosion protection mats to provide nutrients and moisture that promotes vegetation growth. Prefabricated BRC steel basket was used to facilitate and form the reinforced soil wall geometry.

What were the results of the project?

Both the client and contractor were very satisfied with the system and aesthetics of the green wall; it blended extremely well with the earthworks sequence and the system helped to minimize installation down time due to rainfall. It was the best technical and cost effective solution.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG