Company:

Canvasland Holdings Ltd Levin,

Project Details

Fabric 1

Bainflate

Producer:

QCD

Graphics Name

Brett Fraser

Graphics Company

Fraser Signwriting Limited

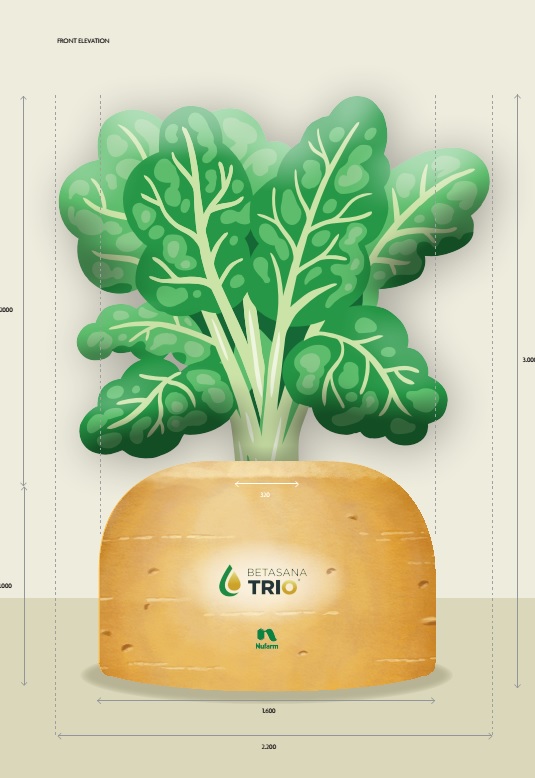

Please describe the project specifications

The inflatable Fodder Beet was conceptualized, designed and manufactured to create awareness of the relatively new crop and maximise their brand exposure.

Bainflate was used as a perfect base for the application of graphics by airbrushing, and a lightweight option. A very effective removable ply base was inserted in a separate chamber at the base of the inflatable to avoid the base from ballooning.

What was the purpose of this project? What did the client request?

Our client requested an inflatable that realistically represented a Fodder Beet, a crop grown from seed for cows; the inflatable was to be used by sales reps of the seed, and at trade shows as a promotional tool.

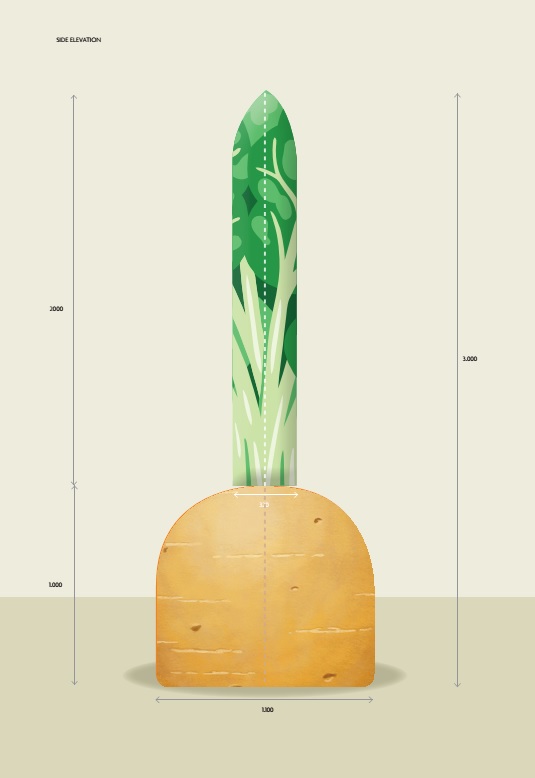

Given its application, the inflatable needed to be lightweight and packaged to a size to allow it to be transported in the boot of a car, and handled by one person.

What is unique or complex about the project?

Fabricating an inflatable fodder beet was unique in itself…the challenge was forming the inflatable essentially into both a 2 dimensional and 3 dimensional shape. The bulb at the base needed to be 3d while the top stayed 2d. Gaining the correct size ‘stem’ to keep in proportion was significant to supply enough airflow to the top as to not create a ‘wilted’ fodder beet.

A separate chamber was installed in the bottom for a removable ply base to be inserted. The ply base was split into four pieces which hinged together to form a ‘slice of pie’. When the base was inserted, lengths of 40x40 box section aluminium tubes were secured across each panel by way of velcro tabs to hold the base flat, as the natural formation of the inflatable would force the ply base to flex. The purpose of the ply base was to hold the bottom of the fodder beet flat and not allow it to balloon; this was a requirement for use at indoor trade shows when fixing to the floor was not an option.

The entire fodder beet was airbrushed by hand, to meet the branding requirements.

An internal blower inflated the fodder beet, and kept noise to a minimum. This allowed the external surface to be free from imperfections and maximised brand exposure with no inlets visible.

What were the results of the project?

We delivered a real life inflatable Fodder Beet, that exceeded our clients brief. The inflatable travels around the country, and can be deployed in under 5 minutes, and is creating great exposure for the relatively ‘modern’ crop.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG