Company:

Beijing N&L Fabric Technology Co., Ltd.

Project Details

Fabric 1

, PTFE fabric Sheerfill-I

Producer:

Saint-Gobain Performance Plastics

Engineer Name 1

Lemei, Wang

Engineer Company 1

Beijing N&L Fabric Technology Co., Ltd.

Design Name

Lemei, Wang

Design Company

Beijing N&L Fabric Technology Co., Ltd.

Architect Company

Gmp Architects

Fabrication Name

Huaisheng,Wu

Fabrication Company

Beijing N&L Fabric Technology Co., Ltd.

Project Manager Name

Binhong,Wu

Project Manager Company

Beijing N&L Fabric Technology Co., Ltd.

Installation Name

Binhong,Wu

Installation Company

Beijing N&L Fabric Technology Co., Ltd.

Please describe the project specifications

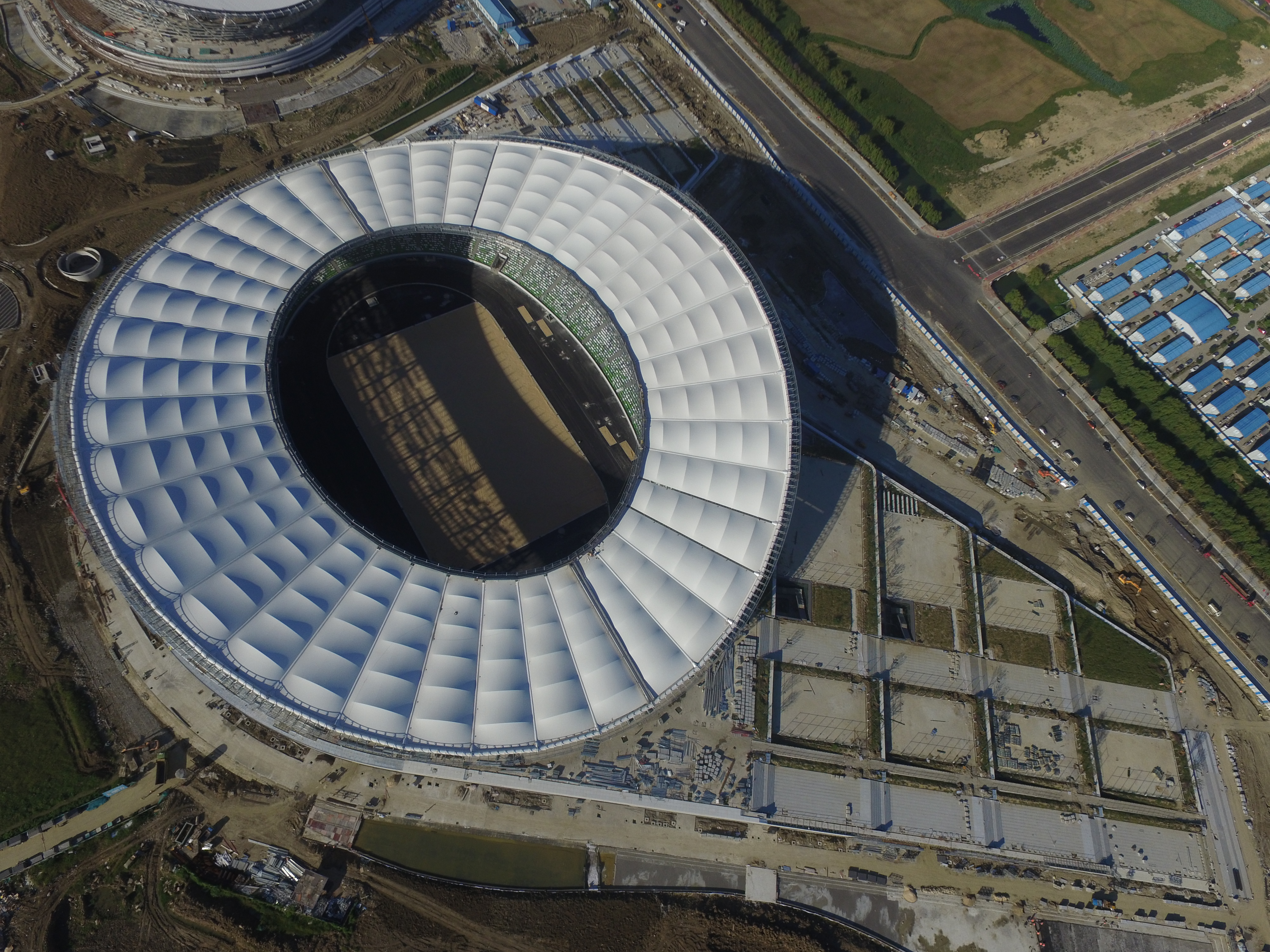

This project is tensile membrane structure supported by single-layer cable system and arch beams. Membrane roof has a saddle surface. Both the inner ring cable and the outer ring beam are double-curvature. Arch beams are arranged along circumferential directions and the ends of arch beams are connected with the radial cables.

The roof is made up of 40 units and membrane area is about 33000 m². Area of the largest unit is 1200 m² and the smallest is 950 m². Plane projection of the roof is an oval. Spans of the roof are about 260 m along the long axis and 230 m along the short axis. Maximum height difference of the saddle roof surface is about 25m.

What was the purpose of this project? What did the client request?

This project was a multi-functional comprehensive stadium for large-scale sports competitions and civic activities that should be ecological, environmental friendly and beautiful.

What is unique or complex about the project?

Because the structure is a single-layer cable-net structure, cables produce great tensile forces on the surrounding steel ring beams, so it is really difficult and important to ensure the stability of the steel structure during forming process of cable system.

Full-locked high strength cables made in Switzerland are used in this project. This kind of cables has favorable mechanical properties and excellent resistance to corrosion and slip.

PTFE fabric Sheerfill-I produced by Saint-Gobain Performance Plastics is used in this project.

Main properties of the Sheerfill-I are as below:

Thickness: (1.0±0.15) mm

Weight: (1570±157) g/m2

Tensile strength: 5400N/3cm (warp); 5000N/3cm (weft)

Tear strength: 391N (warp), 489N (weft)

Elongation at break: 5% (warp), 10% (weft)

Visual Light transmittance: (10±2)%

Sheerfill-I fabric has excellent fireproof performance, self-cleaning and anticorrosion properties.

What were the results of the project?

The construction of this project was finished in October, 2017. Our clients are satisfied with it. Compared with other traditional structures, this project has the advantages of lower cost and shorter construction period.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG