Company:

Baytex Manufacturing Co. Ltd. Mt. Maunganui,

Project Details

Fabric 1

Vinyl, Clear

Producer:

Contender NZ Ltd.

Supplier:

Contender NZ Ltd.

Engineer Name 1

David Barnard

Engineer Company 1

Redco NZ Ltd

Design Name

Andrew Lingman

Design Company

Baytex

Fabrication Name

Grant Ford

Fabrication Company

Rainbow Shade

Project Manager Name

Andrew Lingman

Project Manager Company

Baytex

Installation Name

Andrew Lingman

Installation Company

Baytex

Please describe the project specifications

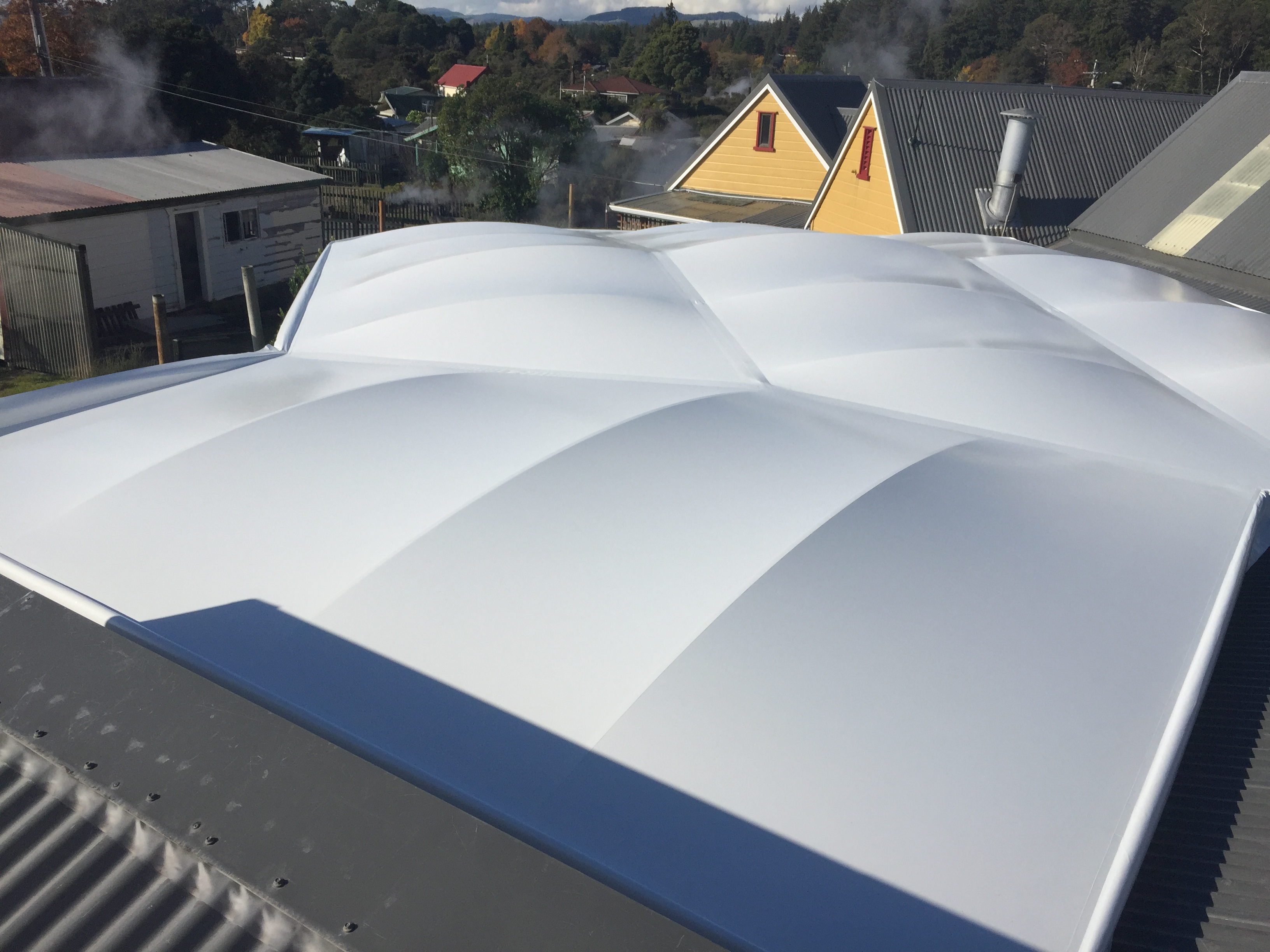

This was a one-piece roof design with an internal arched tensioning system to create a cloud effect providing an all weather café/dining area for visitors to the thermal village. Mounted through an existing timer decking platform to concrete foundations: 12.5m x 11m made from white Ferrari 502.

By walling in the dining area it gives the customers an all weather dining experience while enjoying the thermal scenery. Clear PVC Walling 0.75mm Zip Track Screens in various sizes were a great fit for this environment keeping the steam out of the dining area.

What was the purpose of this project? What did the client request?

To provide an all weather café/dining area for visitors to the thermal village Rotorua NZ in the form of a tensile Cloud Canopy mounted through an existing timber decking platform to concrete foundations: 12.5m x 11m made from white Ferrari 502.

The all weather café/dining area required Zip Track Screens so visitors could feel immersed in the thermal scenery whilst keeping the steam out of the dining area.

Variations in size (x6) screens from 1.9mW up to 2.4mW x 3mH. Clear PVC 0.75mm with Ferrari 502 white trans surround.

What is unique or complex about the project?

This was a one-piece roof with an internal arched tensioning system to create a cloud effect. The canopy had to fit within a unique shape with buildings on three sides. We designed special brackets to sit the structure above existing building gutter lines and make the new café canopy feel like its part of the existing building space.

The Zip Track Screen design needed to fit seamlessly into the framework and hide the Roller Screen system from the outside the Dining Area.

Because of corrosive thermal atmosphere special foundations were required to be designed to ensure their weight didn’t fracture the thermal crust. The finish of the framework is hot dip galvanized and a white urethane 2-part paint finish. Anti corrosive finishes where used on all the internal roller screen moving parts to ensure a long working life.

What were the results of the project?

The client was extremely happy due to their overall dining area and this has led to other projects initiated within the village.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG