Company:

Structurflex Ltd. Auckland,

Project Details

Fabric 1

Précontraint 1302 Fluotop T2

Producer:

Serge Ferrari North America Inc.

Supplier:

Serge Ferrari North America Inc.

Engineer Name 1

A. Cattanach

Engineer Company 1

Dunning Thornton Consultants

Design Name

Harry Kleyn

Design Company

Structurflex Limited

Architect Name

Hugh Tennant / Ewan Brown

Architect Company

Tennant + Brown Architects Ltd

Fabrication Name

Structurflex

Fabrication Company

Structurflex Limited

Subcontractor Name

Structurflex

Subcontractor Company

Structurflex Limited

Project Manager Name

Bernard Hyde

Project Manager Company

Structurflex Limited

Installation Name

Bernard Hyde

Installation Company

Structurflex Limited

Please describe the project specifications

The client requested strong consideration for contemporary design using cost effective materials and a functional space for multiple uses from lawn bowls to concerts and other community events.

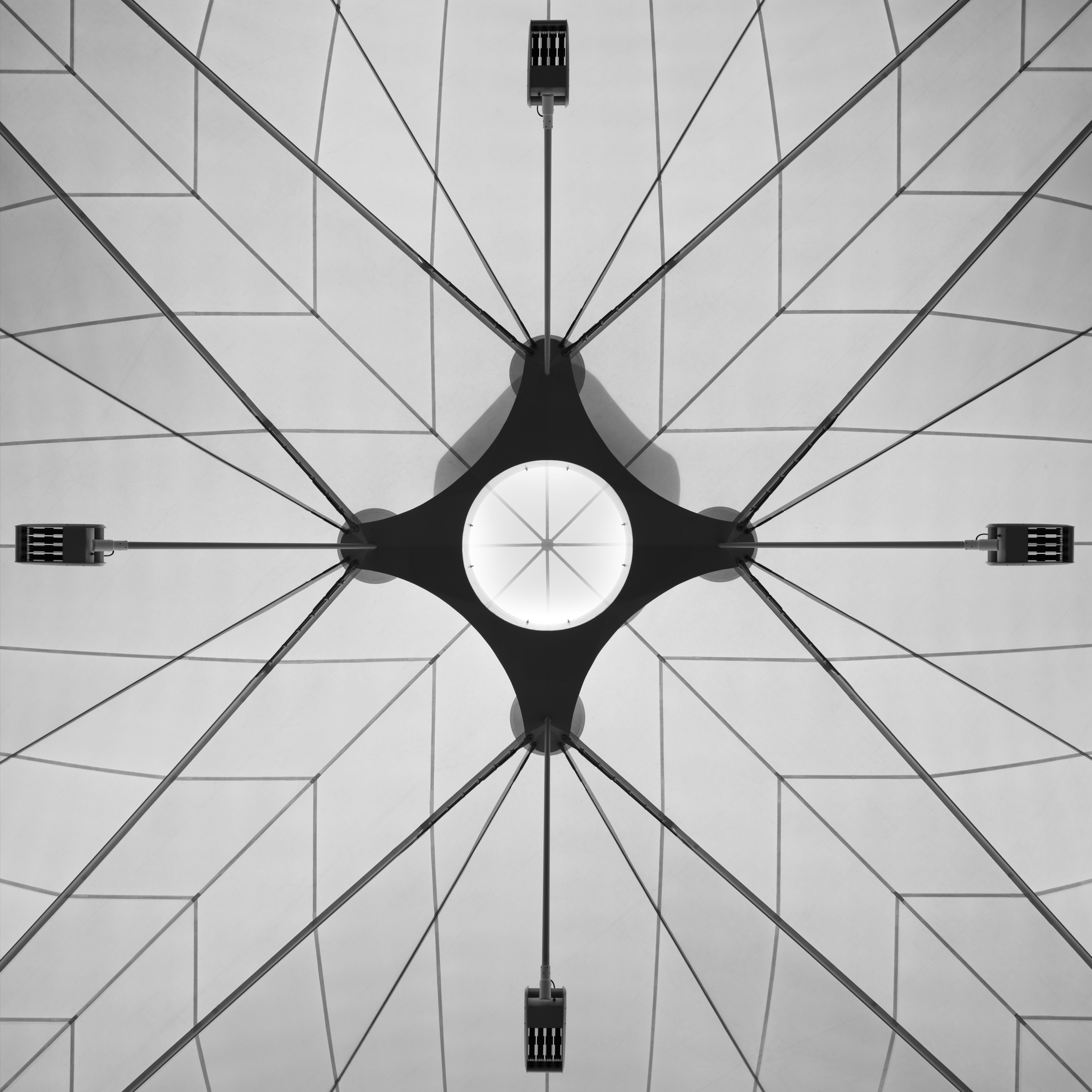

The structure utilises a four arch support system with central bale ring tensioned downward to provide four valleys allowing the catenary effect to provide even fabric pre-stress.

The fabric structure provides a clear span covering two artificial bowling greens, with a high degree of Architectural integrity.

What was the purpose of this project? What did the client request?

This overall project was specifically conceived and designed to provide a community meeting point to focus and reinvigorate the residents of a depressed suburb which had been in steady decline for 30 plus years. Many residents of this suburb are elderly and due to transportation access and costs seldom left their homes, hence social integration and community interaction was poor. The additional aim of the project was to have the elderly and young be involved in community based sports and activities to invigorate, inspire, and bond fellow citizens.

The client requested a facility that would provide a modern strong and striking aesthetic focal point for the community. Strong consideration for contemporary design using cost effective materials and building solutions and a highly functional space which could be adapted for use from indoor and outdoor lawn bowls to concerts, big screen movies and other community organised events was paramount.

The requirement of minimising consumption of resources for heating, ventilation and lighting was to be incorporated into the design. The fabric shape with central ring provided for heat to rise and escape– when the large glazed doors are opened a natural draft is created which significantly cools the bowling green area. The tilt up slab walls and large concrete apron of significant thermal mass heated by the sun during the day, provide for re-radiated heating in the cool winter evenings. Highly translucent fabric allows for natural light to evenly illuminate the bowling green during the day hence negating the use of lighting with low energy LED up-lights used at night to evenly light the reflective fabric surface, eliminating shadows and areas of indifferent light levels to the playing green surface.

The use of a large span Tension membrane structure provided the “nucleus” from project inception through to final design.

What is unique or complex about the project?

The client had acquired an existing dilapidated sports facility in the centre of the community; however the geological area was part of an ancient riverbed consisting of unstable sedimentary material which was found to be extremely sensitive to liquefaction during seismic activity.

The design of the building and in particular the Tension Membrane Structure had to accommodate for signification lateral displacement under seismic conditions .This lead to development of a complex structural steel design and base isolation that would allow for movement and return to design geometry after a seismic event given the "importance level" of this public space .

Due to the specific seismic design the installation process of the structural steel and Tensioned Membrane Structure was a very sensitive process.

A very detailed engineered installation plan was developed, incorporating temporary support towers with sliding bogies to allow the structural steel arches to transit fore and aft during installation to avoid unbalanced forces imparting loads into the rigid bracing elements of the surrounding building. Twice as much time was spent in the office planning and designing the installation as did the actual installation on site of approximately six weeks.

To provide added aesthetic qualities for the membrane a hearing bone pattern was developed into the valley regions of the structure - this complicated the fabrication process with very complex gore seam overlaps. This addition detail was well worth the effort adding a real sense of craftsmanship to the project. Project photos speak for themselves.

What were the results of the project?

The project was successfully completed with a very satisfied client and an outstanding community facility that has been fully utilised from the first day of opening

The club membership has increased from some 80 members that used the decrepit facility occasionally to over 400 and climbing that now use the facility daily. The community acceptance and integration has been tremendous.

Revenue raised from the restaurant and bar incorporated into the facility help fund the club and community events planned there.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG