Company:

TenCate Geosynthetics Americas Pendergrass, GA

Project Details

Fabric 1

Geotube®

Producer:

TenCate Geosynthetics Asia

Supplier:

TenCate Geosynthetics Asia

Fabric 2

Mirafi

Producer:

TenCate Geosynthetics Asia

Supplier:

TenCate Geosynthetics Asia

Fabric 3

Polyfelt PEC

Producer:

TenCate Geosynthetics Asia

Supplier:

TenCate Geosynthetics Asia

Engineer Name 1

Regional Director Allan S. Borromeo / Engineer Teofila U. Tan

Design Company

DPWH Region 11 Planning and Design Division

Project Manager Company

DPWH Region 11 Construction Division

Installation Company

RELY Construction and Supply, Hi View Resources and Development Corporation, Wee Eng Construction Inc., Ulticon Builders, Inc.,

Please describe the project specifications

Traffic volume in Davao City has been increasing recently due to its population and economic growth. In the inland part of the city, the majority of people depend on vehicular public transportation services such as jeepneys, tricycles, and buses which contribute a lot to the worsening of the traffic congestion. The Davao City Coastal Road aims to abate and address the traffic congestion in the city by diverting private vehicles passing from the downtown area. The project will also improve inter-regional transport of goods and services passing through the city, as well as support the growth of the agro-industrial sector. Apart from that, the project aims to serve as a tourism facility as esplanades, where parks, playgrounds, outdoor theater and botanical gardens shall be constructed.

What was the purpose of this project? What did the client request?

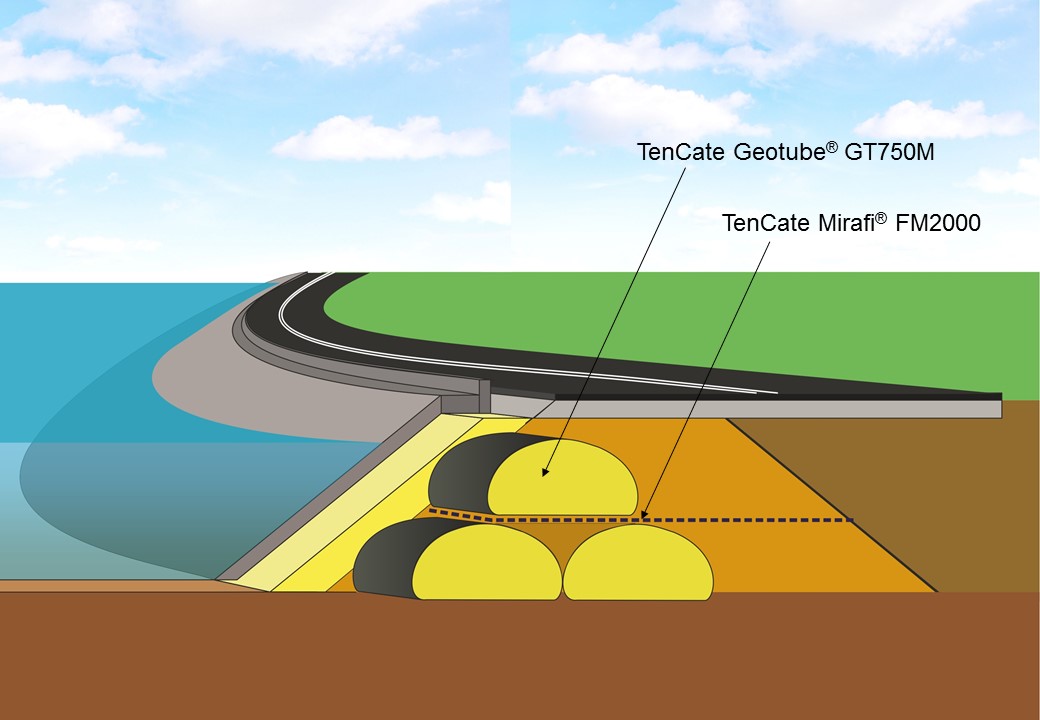

The first of the five segments of the project, Segment A, covers 1.79km along the coastline, costing PHP 1.96 billion. It started in September 2017 in Talomo, Davao City. The initial phase of the project consisted of reclaiming 30 meters from the existing shoreline in order to construct a stable working platform for the coastal road project. Reclamation works were done using our Geotube® systems. Geotube® GT750M geotextile tubes replaced the conventional laying of boulders as there is scarcity in the supply of armor rocks in the region. In-situ sand filling of the geotextile tubes offers (i) a more economical solution with guaranteed speedy construction of the seawall, compared to the conventional method of importing core rocks using barge; (ii) a more environmentally friendly solution with less carbon emissions due to less import material being required. The sandy materials dredged in the area were also used in filling the tubes which made the project more economical.

What is unique or complex about the project?

Initial works of the project consisted of furnishing and laying the GT750M geotextile tubes using A-Frames for alignment in order to serve as an edge dyke and revetment protection. The geotextile tubes were filled hydraulically to 2m high, 25lm length and 12.6m circumferences by pumping sand slurry through the filling ports. To allow flow of fill material, the fill was in the form of sand/sea water slurry. The GT750M geotextile tubes, being permeable, allowed the water to pass through the fabric while the sand was being retained inside the tubes. Prior to the filling the embankment of earth fill, Mirafi® FM2000 woven filter geotextiles were installed to serve as a basal reinforcement of the structure. To make the tubes a permanent mass gravity structure, a layer of Polyfelt® F68 filtration geotextiles were laid to protect it from punctures from the overlying boulders.

What were the results of the project?

As of today, the installation of the geotextile tubes in Segment A of the project is completed. The flexibility of geotextile tubes sped up the completion time of Segment A with less labor required, due to the mechanical method of installation. The output of the project made and impact with other Departments of Public Works and Highways (DPWH), regions, and district offices. New coastal road projects in Davao Oriental, Butuan City, Cagayan de Oro and Leyte are being designed using geotextile tubes to enhance the socio-economic of the Philippines.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG