Company:

Signature Structures LLC Easton, PA

Project Details

Fabric 1

Précontraint 1202 Fluotop T2

Producer:

Serge Ferrari North America Inc.

Supplier:

Serge Ferrari North America Inc.

Engineer Name 1

Dirk Cos

Engineer Company 1

LDI

Fabrication Name

Lightweight Manufacturing

Fabrication Company

Lightweight Manufacturing

Project Manager Name

Curtis Mita

Project Manager Company

Signature Structures LLC

Installation Name

Dennis Johnson

Installation Company

Signature Structures LLC

Please describe the project specifications

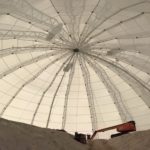

Our company provided a replacement membrane cover a salt storage enclosure that was approximately 160' diameter consisting of 16 separate pie shaped panels that were supported by cables suspended from exterior trusses. We provided design, engineering, project management, fabrication and installation services for the project.

What was the purpose of this project? What did the client request?

The fabric on the structure had out lived its life expectancy and needed to be replaced. It was completely delaminated and subject to failure. In addition, much of the hardware was corroded and required replacement, as often happens in salt storage structure. The client wanted a new replacement membrane as well as refurbishment of all structural components to allow them to utilize the enclosure for another 20 years.

What is unique or complex about the project?

The structure itself is very unique and complex and features many design characteristics not common on membrane fabric structures in general and certainly not for a commodity storage application. For example, the fabric was suspended below the trusses from cables instead of fastened to the exterior of the trusses. This was most likely designed to remedy a common problem of salt storage structures- corrosion of the trusses. All other structural elements (purlins, cables) were also mounted to the exterior of the structure. The trusses themselves were of a unique design not at all commonplace in the industry. To top it off, much of the original engineering was unavailable; thus the structure had to be reversed engineered in order to design the replacement systems. The City and the General Contractor needed a company capable of offering a full range of services to affect this refurbishment.

What were the results of the project?

Our company provided a brand new membrane cover constructed of a superior material to the original. We designed the new cover, provided stamped engineering to allow client to obtain all required permits, supplied project management services and installed the new cover and refurbished all other elements of the structure overcoming all of the unique obstacles to put in front of us. As a result, the City of Cincinnati has a salt storage enclosure that for all intents and purposes will function like a brand new facility, matching the life cycle provided by the original manufacturer.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG