Company:

Taiyo Europe GmbH Sauerlach,

Project Details

Fabric 1

Duraskin B 18089

Producer:

Verseidag-Indutex GmbH

Supplier:

Verseidag-Indutex GmbH

Engineer Company 1

Schlaich Bergmann Partners, Maffeis Engineering SpA, Taiyo Europe GmbH

Design Company

Cruz y Ortiz Architectos

Architect Company

Cruz y Ortiz Architectos

Fabrication Company

Shanghai Taiyo Kogyo Corp.

Project Manager Name

Mr. Andrejus Cernysevas

Project Manager Company

Taiyo Europe GmbH

Installation Company

Taiyo Europe GmbH, Montageservice LB GmbH

Please describe the project specifications

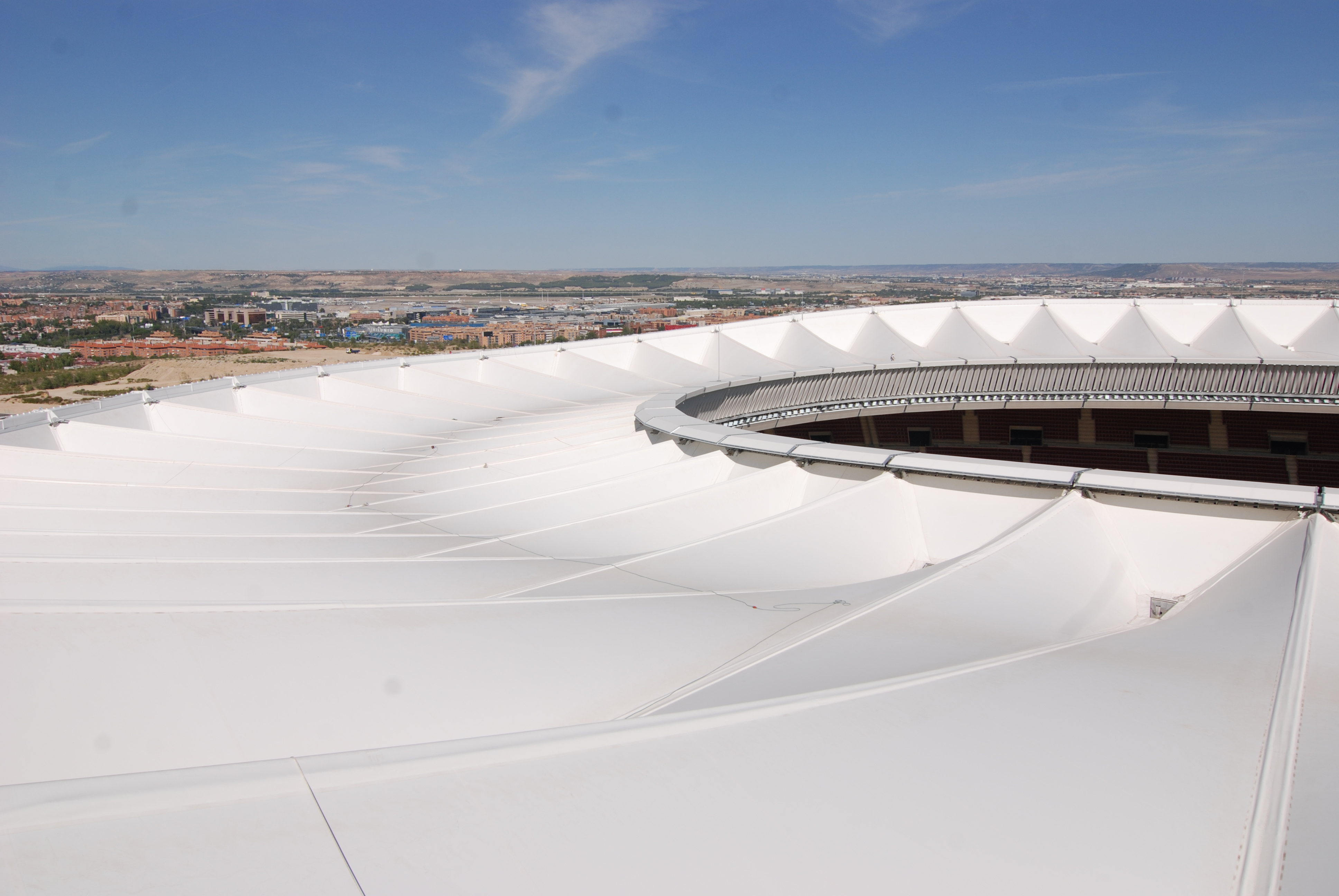

Atlético Madrid is one of the most technologically advanced and breathtaking football stadiums in the world. Despite the capacity of 68,000 seats for spectators, which are located immediately in the vicinity of the game, a sense of luxury and space is conveyed. The total weight of the roof is approximately 850T not including the compression ring steel or the cantilever canopy roof which is behind the stadium bowl. The cable net alone weights nearly 600T. This specific type of the roof – tension structure – allows architects to achieve most complex forms. The light weight elements such as cables, and PTFE glass can flex in to anticlastic form providing both stable structural system and bespoke curvatures. The PTFE glass is essentially “cool, low embodied energy roof”. Such a low ratio of building material kg per m2 of covering cannot be achieved in any other type of the structural system. PTFE glass is truly remarkable new generation material. Around 70% of the sun energy is reflected back in to atmosphere while 10% of light is transmitted through the material providing beautiful ambient light inside the stadium. On a game night the roof reflects the artificial lights and the crowd noise back in to the pitch. The amplified sound creates real pressure-cooker for fans and the players.

What was the purpose of this project? What did the client request?

Taiyo-Europe was selected as a partner to deliver this visionary and immensely complex light weight roof. Our involvement began in 3rd quarter of 2015. Our contract included fine tuning of the engineering design detailing of all the elements of the roof, analysis and execution of the assembly and lifting of the cable net, complete procurement and installation of the cable net roof including all the structural elements attached to it and cladding of more than 83.000m2 of PTFE glass membrane.

What is unique or complex about the project?

The complexity of the work and very tight schedule required some unprecedented solutions to be implemented. One of the first steps in the execution of a cable net roof is to make decision about the lifting method of the roof. This decision has far fetching economical and buildability consequences and it is next to impossible to change in a later stages of the project. The lifting of the cable net roof is by far one of the most state-of-the- art engineering and heavy lifting operations there is. To be involved and lead such an extravaganza is an icing on a cake for any construction professional. Installation of the main radial panels, approximately 400m2 each, has to take place 50m in the air. Each panel is lifted and stored on the compression ring and then unrolled and tensioned attaching to the radial cables. The entire compression ring and also the 15,000m2 cantilever roof hovering outside the main stadium bowl is covered in PTFE glass membrane. The upper side of the roof is cladded with solid PTFE and provides waterproofing and shading while the underside is cladded with PTFE open mesh material delivering truly clean and finished look to entire structure.

What were the results of the project?

There are many unique steps in this construction however one particular solution proposed by Taiyo-Europe and our partners has made the opening of the stadium possible on the 16th of September 2017. The challenges in the execution of the complex construction on extremely short schedule together with the high standards required for the installation in height on the large construction site were managed by Taiyo Europe GmbH with commitment and skill.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG