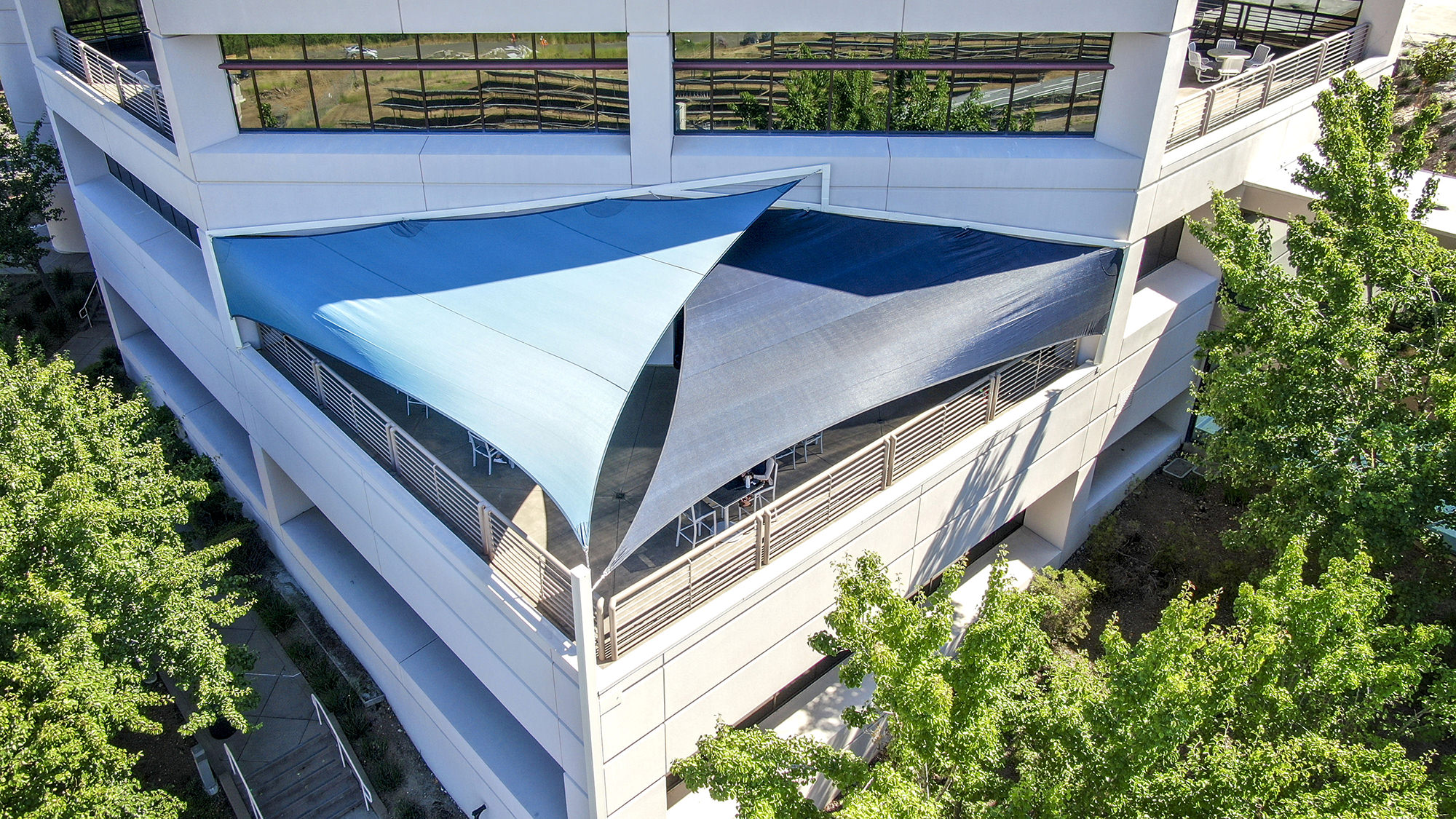

Company:

Sonoma Shade Sails Forestville, CA

Project Details

Fabric 1

Alnet Extrablock - Navy & Dove Blue

Producer:

Engineer Name 1

Mike Sullaway

Engineer Company 1

Sullaway Engineering

Design Name

Andrea Lynn

Design Company

Sonoma Shade Sails

Fabrication Name

Patrick Howe

Fabrication Company

Wholesale Shade

Project Manager Name

Bob Brouwers

Project Manager Company

Sonoma Shade Sails

Installation Name

Second Story Shade

Installation Company

Sonoma Shade Sails

Please describe the project specifications

This project presented itself as a 45' x 45' x 60' triangular exterior patio on the 2nd Story of a Commercial EIFS coated building. South/Southwest exposure made the patio unusable along with the high solar gain in the offices.

What was the purpose of this project? What did the client request?

The purpose of this design was to create a unique working space for their engineers. We were asked to transform this outdoor patio into a creatively cool, protected, and usable space for these young professionals. The Client asked us to design, engineer, fabricate and install shade sails on this elevated patio.

What is unique or complex about the project?

3- In a word? Everything was complex and unique in this project. To begin with, finding the attachment location possibilities was a monumental task between the engineer and our team. Behind the exterior EIFS coating, 24" deep, a 28" steel I beam spans the 60' wall. On each side a series of 3 attachments tied back to the I beam with descending heights from the apex was designed. A 60’ - 2" x 8" custom steel bracket mirroring this attachment pattern was fabricated. The bracket was divided into sections for powder coating protocol then securely bolted together. The moment of truth arrived when the crane lifted the 60’ bracket into position. It was spectacular to watch the bracket slowly ascend to and hover above the corner patio. The ground crew holding the ends of long training ropes to prevent the bracket from spinning; and then it gently touched down. The collective skills of our team beamed when 6 wall attachments with only a 3" tolerance slid into place and the feet bracketed the side walls. Next was lifting the 30' long 8" x 8" corner post, also fully powder coated onto the side of the building. Singularly it would have been exciting, but it was relatively anti-climactic by comparison to the wall bracket air adventure. The attachment phase was now complete, but our fabricator had his work cut out for him. Each sail had 4 bracket attachments that ended into a 90 degree turned K rail attached to the wall and then back to the corner post. The fabricator nailed the sails the first time.

What were the results of the project?

This Client was beyond happy with the project. It achieved the shade profile promised and the cooling effect to the building is substantial. They commissioned us to design 3 other elevated patios and a green space.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG